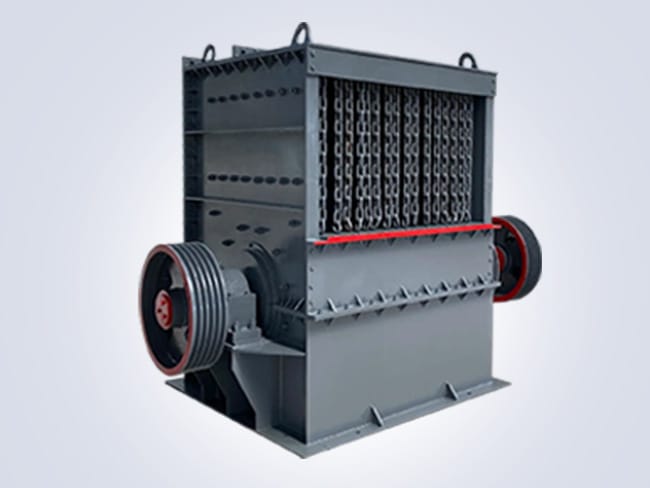

The box-type crusher is a common crushing equipment widely used in fields such as mining, construction, and highways. Its crushing process is highly efficient and precise, bringing significant convenience and benefits to the production process.

Crushing Process of the box-type crusher

In the crushing process of the crusher, materials are first fed into the crusher’s inlet. They are then rapidly crushed within the crusher chamber due to the action of high-speed rotating hammers and impact plates. The high-speed rotation of the hammers and the impact force cause the materials to fall from a higher point. Generating strong impact and shear forces, thus achieving rapid crushing effects.

The crushing chamber of the box-type crusher is designed specially, allowing materials to be uniformly stressed during the crushing process, reducing wear and extending its lifespan. Additionally, the crusher is equipped with efficient dust removal devices, effectively reducing dust pollution and protecting the environment.

During the crushing process, the box-type crusher also has the function of adjusting particle size. By adjusting the position and angle of the impact plates. The particle size of the crushed materials can be controlled to meet different production needs. This precise control has led to the widespread application of the crusher in various fields, enhancing production efficiency and product quality.

In summary, the box-type crusher’s crushing process features high efficiency, precision, and adjustability, bringing convenience and improvement to the production process. It not only enhances production efficiency and reduces production costs but also provides robust support for the development of various industries.