The vibrating screen, widely employed in industries such as mining, metallurgy, building materials. Chemicals, and food, serves as a critical material classification device due to its efficient screening and precise separation capabilities. Which significantly contribute to enhancing product quality and optimizing production processes.

What are the key functions of a vibrating screen

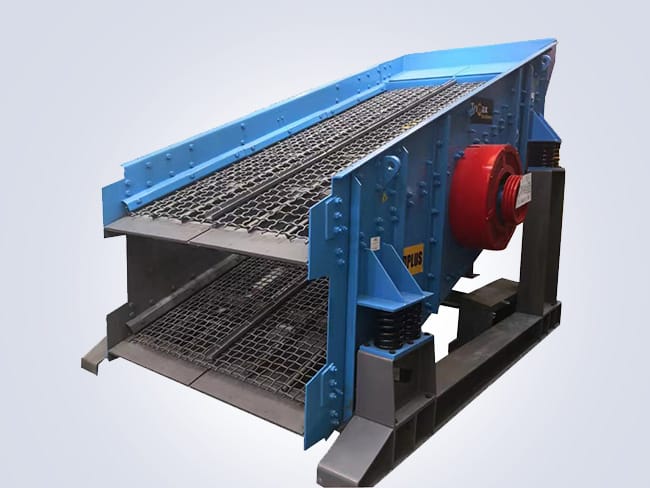

A vibrating screen primarily comprises components such as the sieve box, vibrator, damping springs, and support. During operation, the vibrator generates high-frequency oscillations, causing the entire sieve box. And the attached sieving mesh to move in a regular pattern. This motion propels the material on the screen surface to undergo a tossing. And leaping progression. facilitating the separation of particles according to their sizes. Its core strengths manifest in the following aspects:

Efficient screening capacity: By adjusting parameters such as vibration frequency, amplitude. And sieve inclination angle, the equipment precisely controls the material’s movement speed and dwell time on the screen. Enabling it to accommodate varying material properties and screening requirements. This results in highly accurate and efficient grading and sorting.

Wide applicability: Vibrating screens come in a diverse range of types, suitable for sieving various granular and powdered materials. They effectively handle everything from coarse aggregates like ores and gravel to fine powders and crystals, as well as sticky and moist substances, fulfilling the diverse needs of industry.

Excellent durability and ease of maintenance: These devices are typically constructed from high-quality steel, boasting high structural strength, robust resistance to wear, and corrosion. Sieve mesh replacement is convenient, and spare parts exhibit strong interchangeability, facilitating routine inspections and maintenance. This ensures the equipment’s long-term, stable operation while minimizing operating costs.

Environmental friendliness and energy efficiency: Contemporary vibrating screen designs prioritize dust emission reduction, incorporating features such as sealed enclosures. And spray dust suppression systems, aligning with green production standards. Additionally, they employ efficient vibratory sources and optimized power transmission methods, resulting in low energy consumption, conforming to the industrial trend of energy conservation and emissions reduction.

In summary, with its outstanding screening performance, extensive applicability, commendable durability and ease of maintenance, as well as environmentally friendly and energy-efficient attributes, this equipment plays an irreplaceable role in the material classification stages across various industries, establishing itself as an indispensable piece of equipment in modern industrial production.