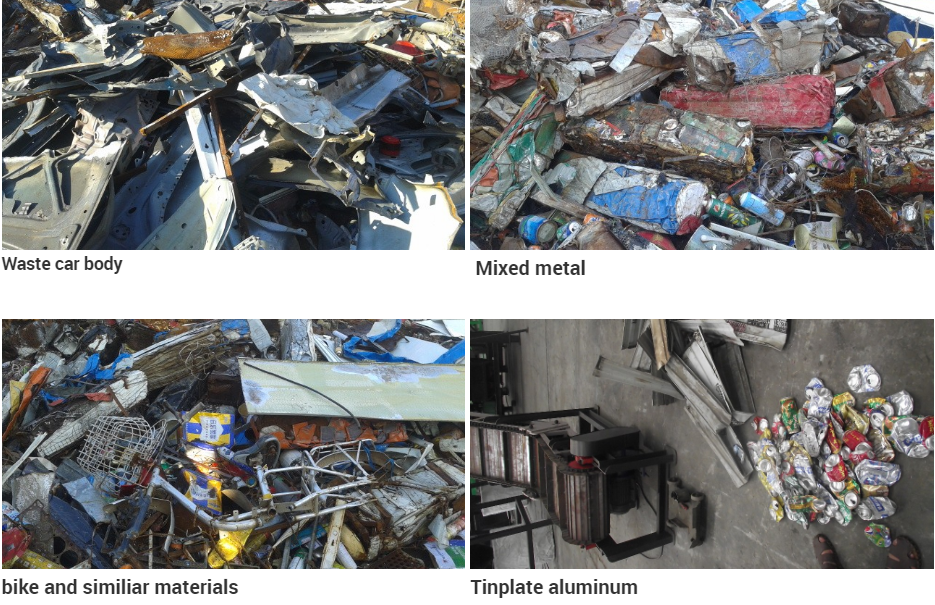

Applicable materials:metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Application scope: metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Metal crusher, also known as metal crusher, is a machine for crushing scrap metal materials. According to the different crushing materials, it can also be called scrap iron crusher, can crusher, scrap steel crusher, paint bucket crusher, etc. These are general equipment for metal crushers. The metal crusher is equipped with qualified production line equipment, which is a perfect set of metal crusher production line equipment.

The waste paint bucket crusher feeds the steel from the inlet into the machinery inside and crushes the metal materials in the cabin of the crusher. When crush the metal materials, the screen fixed in the bottom of the crusher, and the crushed metal particles will come out from the discharge port when the size reaches to the screen size.

The texture of the waste paint bucket crusher blades adopts type 63 manganese. Usually the design of the cutter is a row of blades and a row of hooks, which is more conducive to crushing metal and have faster effect as well.

Application Ranges

The nick names of the waste paint bucket crusher are steel scrap crusher, color steel tile crusher, bicycle crusher, motorcycle crusher and car shell crusher etc. The crushing material metal of crusher includes Sprite cans, lulu cans, red bull cans, and coke cans. It is not only can crush drink cans, but also can crush paint cans, machine oil tank and so on. The crushed material is very easy to carry and convenient to steelmaking. The time of feeding steel is also reduced a lot.

Working Principles

In the crushing process, external pressure pressed on the solid includes rolling, clipping, impact, grinding. Pressure rolling is mainly used in the coarse crusher, suitable for hard material and bulk material crushing; Clipping is mostly used in fine grinding, suitable for crushing the ductile material; Impact is mostly used in the crusher, fine grinding, super fine grinding, and suitable for crushing the brittle material; Grinding is mainly used in the fine grinding, super fine grinding, and suitable for crushing the small pieces. The actual crushing process is often conducted with the effect of several forces at the same time.