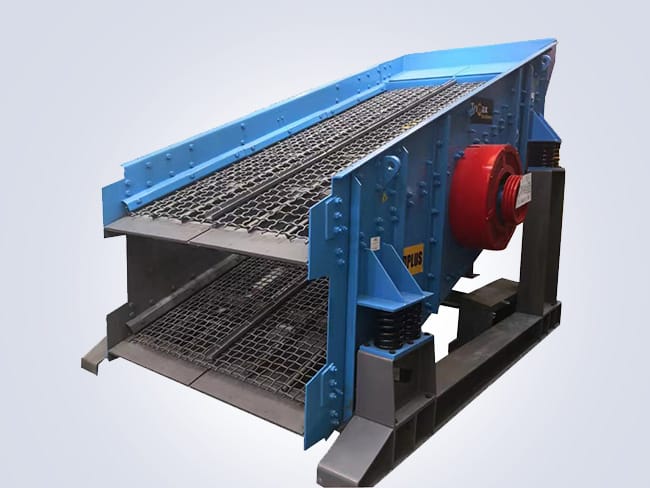

The vibrating screen is a commonly used solid particle separation equipment. Which works by sieving the material through the vibrating screen mesh to achieve separation of particles of different sizes. It is widely used in various fields such as chemical industry, food processing, building materials, metallurgy, etc. And plays an important role in improving production efficiency and ensuring product quality.

The vibrating screen improves screening efficiency

Firstly, this equipment uses a vibrating motor as the power source to generate high-frequency vibration in the sieve body, effectively promoting the movement of materials on the screen mesh. This vibration motion can quickly disperse the material during the screening process, avoiding accumulation, thereby improving screening efficiency.

Secondly, the equipment uses screens of different specifications to accurately separate materials of different particle sizes. By replacing the screen, it can meet the screening requirements of different materials, showing high flexibility and applicability.

Additionally, it has a simple structure, convenient operation, and low maintenance costs. It is usually composed of components such as the screen box, vibrating motor, and screen mesh, with a compact structure and small footprint, suitable for various production scenarios.

Finally, the equipment also has advantages in environmental protection. The screen materials used are mostly wear-resistant and corrosion-resistant alloy materials, with a long service life, reducing the frequency of screen replacement and lowering production costs. At the same time, the vibration noise generated during the screening process is relatively low, with minimal environmental impact.

In summary, as a precision screening tool, the vibrating screen plays an important role in industrial production. It not only improves production efficiency and ensures product quality but also has many advantages such as energy saving, environmental protection, and easy operation. It will be more widely applied and developed in the future.