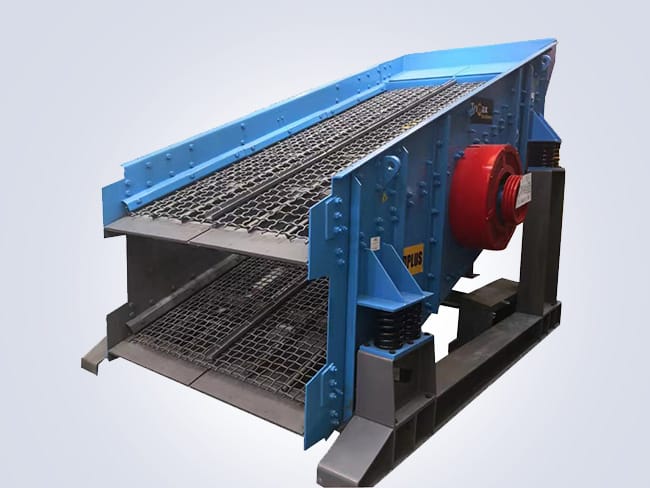

The vibrating screen is a common screening device widely used for the separation and sieving of particles, powders, and other materials. Its operational principle involves inducing relative motion in materials on the sieve surface through vibration, thereby achieving the separation of materials of different particle sizes. It plays a significant role in both industrial production and laboratory settings.

Advantages and characteristics

One of the notable advantages of this equipment is its efficient screening effect. By applying vibration forces, materials continuously jump and roll on the sieve surface, facilitating the separation of particles. This movement leverages the inherent characteristics of the materials, leading to improved screening efficiency.

Furthermore, the equipment boasts features of flexible adjustment and easy operation. By modifying the magnitude and direction of vibration forces, it’s possible to achieve the sieving of materials with varying particle sizes. During the screening process, operators only need to monitor the equipment’s operational status and make adjustments as necessary, allowing for automated separation tasks.

Application fields of vibrating screen

The equipment finds extensive applications across various fields. In the food industry, it’s employed for screening grains, sugar powder, starch, and other materials to enhance product quality. In chemical and pharmaceutical manufacturing, it’s used to separate particles and powders, ensuring product purity and consistency.

However, there are certain considerations when using this equipment. First, it’s essential to choose an appropriate model and specifications to ensure that the equipment meets production requirements. Second, regular checks on the operational status and maintenance of the equipment are necessary to ensure its smooth and stable operation. Lastly, adhering to operational protocols during the screening process is crucial to prevent improper operations from affecting the screening efficiency.

In summary, this equipment is a vital screening device that achieves material separation and sieving through vibration forces. Its efficient and versatile screening capabilities make it widely applicable across various fields. When procuring and using the equipment, attention should be paid to aspects such as model selection, maintenance, and operation to ensure the seamless progress of screening tasks.