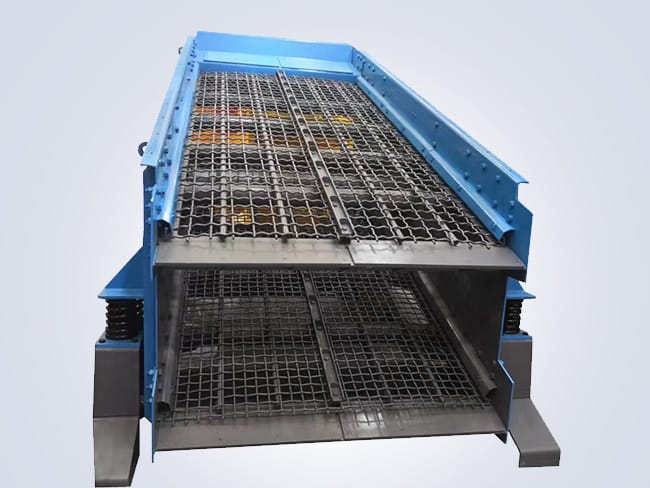

The importance of vibrating screen in modern industrial production cannot be underestimated. Especially in industries such as mining, metallurgy, building materials. And chemicals, where they are key equipment for material grading and screening. Their design enables them to efficiently and precisely complete the separation of materials. Thereby ensuring the smoothness of the production process and the consistency of product quality.

The Importance of Vibrating Screen

Firstly, vibrating screens can effectively classify materials by size or density through rapid vibratory motions. This classification is crucial for ensuring the uniformity of materials in subsequent processes and improving product quality. For example, in the construction industry, this equipment can ensure the uniformity of aggregate sizes used in concrete, thus guaranteeing the strength and durability of the concrete.

Secondly, the efficiency of vibrating screens is also reflected in their energy saving and production efficiency enhancement. Compared to traditional screening methods, they can handle a larger volume of materials while occupying less space, reducing energy consumption, and completing the screening of a large amount of material in a shorter time.

Lastly, the application of the equipment greatly improves the safety of the working environment. It reduces the need for manual direct contact with materials through automated operations, lowering health risks for workers.

In summary, as an indispensable piece of equipment in modern industry, vibrating screens play a significant role in enhancing production efficiency, ensuring product quality, and reducing production costs.