The vibrating screen is a widely utilized screening device in industrial production. Primarily used for grading, removing impurities, and dewatering materials. Its basic working principle involves using the excitation force generated by a vibrating motor to induce screening motion in the material on the screen surface. Thereby achieving the separation of materials with different particle sizes.

Structure of the Vibrating Screen

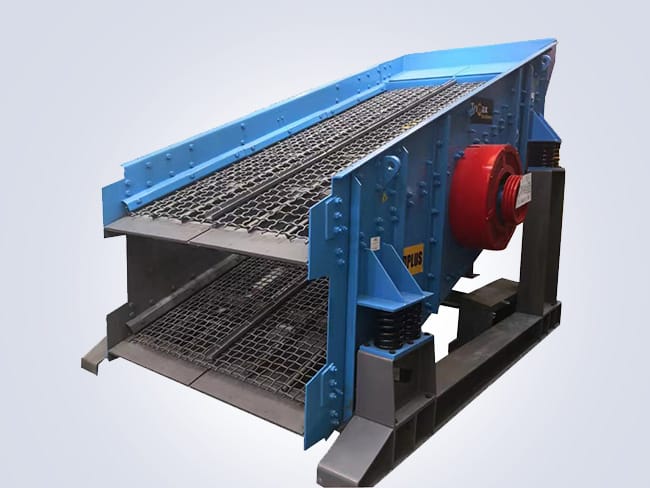

The equipment’s structure mainly includes a screen box, screen mesh, vibrating motor, damping device, and base. The screen box serves as the frame for mounting the screen mesh and other components. With the vibrating motor causing the screen box to vibrate through the exciter. The screen mesh is the key part for screening materials, and different materials. And screening requirements can be met by choosing meshes of various materials and apertures. The damping device is used to reduce the impact of vibrations on the foundation and surrounding environment, enhancing the equipment’s stability and service life.

Based on different screening methods and structural features, the equipment can be classified into linear, circular, and ultrasonic types. The linear type is suitable for coarse screening of large particles, offering high screening efficiency and large processing capacity. The circular type is suitable for grading medium and fine particles, providing high screening precision. The ultrasonic type employs ultrasonic vibration to further improve the screening efficiency of fine particles and is widely used in the fine powder industry.

The vibrating screen has significant applications in industries such as mining, coal, building materials, chemicals, and food. For instance, in the mining industry, it is used for ore grading and impurity removal; in the food industry, it is used for screening grains and powdered foods. In the environmental protection industry, it is used for solid-liquid separation in wastewater treatment.

In conclusion, as an efficient and stable screening device, the vibrating screen has found widespread application across various industries due to its simple structure, easy operation, and high screening efficiency. In the future, with continuous technological advancements, vibrating screens will develop towards higher efficiency, greater precision, and better energy-saving, providing stronger support for industrial production.