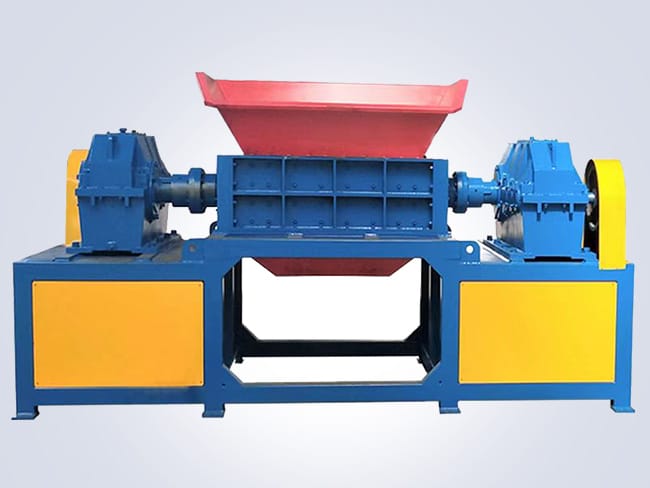

The wood shredder, as an efficient wood processing equipment, is highly popular for several reasons:

Firstly, compared to traditional manual or mechanical methods of felling wood. This equipment can grind large pieces of wood into the desired particles within a short period, significantly improving production efficiency. Moreover, the equipment employs advanced technology, allowing it to maintain relatively low energy consumption during operation, saving energy. And reducing production costs.

Reasons for the popularity of the wood shredder

Secondly, the equipment is easy to operate, featuring an automated control system and a user-friendly interface. Operators can master the skills with simple training. This convenient operating method enhances the efficiency of the production line and reduces labor costs.

The equipment is versatile. The shredder can handle wood of various hardness and moisture levels and is suitable for processing various waste materials such as discarded furniture, construction debris, branches, and leaves. Therefore, it has a wide range of applications, suitable for wood processing, biomass energy production, and many other fields, greatly expanding its utility.

The equipment contributes to the recycling of resources. Through the shredder’s processing, discarded wood can be reused to produce products such as wood pellets and wooden boards, promoting the recycling of resources and reducing dependence on natural resources.

In summary, the wood shredder is popular not only because of its efficiency, energy conservation, ease of operation, and versatility but also because it contributes to the recycling of resources, driving the sustainable development of the wood processing industry. With continuous technological innovation, we believe the wood shredder will have even broader prospects in the future.