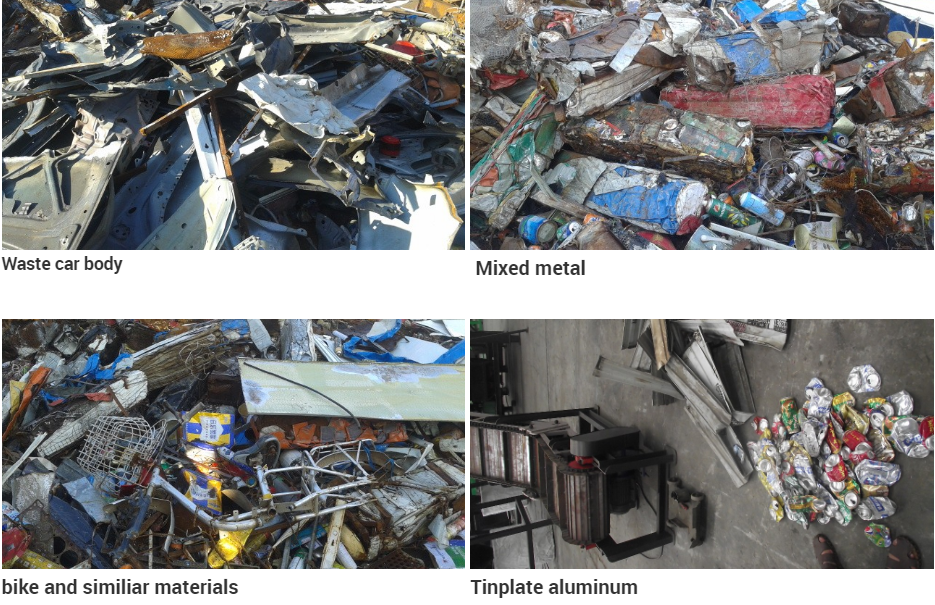

Applicable materials:metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Application scope: metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Metal Crusher is the latest type crusher which is produced according to the requirements of the market who organizes the power and combines the specific practical application of the clients from home and abroad. It is very high-efficiency and energy-saving. In addition, this machine has the characters of high convenience, compact composition and large capacity.

According to scraped materials size the mill can be divided into primary crusher, crusher, fine grinding machine and ultrafine mill. The metal crusher includes the machine parts are gear motors, chassis, racks, helical cutter combination, drive shaft, the driven shaft, gear, pinion and other parts. It is mainly applied to the large-scale reclamation depot and used to break the cans into ideal pellets, such as drink can, beer can, so that the transport cost can be reduced. The users can adopt different allocations according to the materials species, scale, and the requirements of the finished goods.