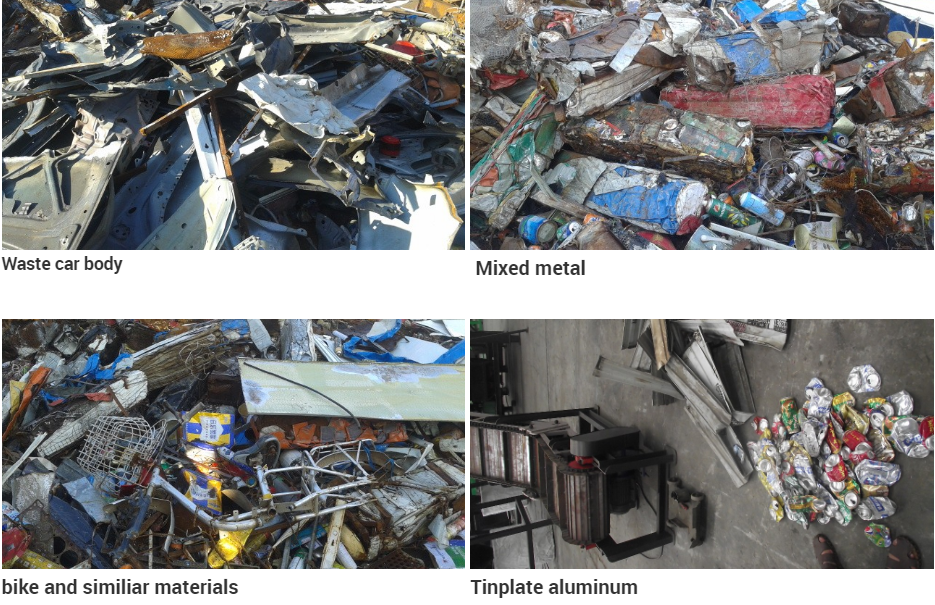

Applicable materials:metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Application scope: metal crusher, such as scrap metal, cans, caging watts, paint bucket, motor shell, motorcycle and bicycle rack shelf etc.

Metal can crusher is mainly focuses on waste recycling market and small or medium-sized recycling market. It is used to crush the iron bucket, bucket of aluminum, tin cans, paint cans and other processing, so as to achieve for transportation, facilitate the aim of regeneration. We can design the most suitable device models for your business according to your requirements and recommendations.

Metal can crusher is mainly applied to the large scale reclamation depot and used to break the cans into ideal pellets, such as drink can, beer can,oil barrel, paint cans, powdered milk cans etc, so that the transport cost can be reduced. The users can adopt different allocations according to the materials species, scale, and the requirements of the finished goods.

Application

Metal Crusher is used to crush all kinds of waste metal materials such as waste car body, home appliances, bicycles, empty cans. tinplate and so on. It can turn them into a superior steel materials after crushing and separating. Through continuously crush to remove the coating and increase bulk density thereby prevent explosion when they are put into the electric furnace, which can increase solubility in certain state and make the high concentrated materials to be put into the furnace.

Working principle

The basic principle is using motor to drive wind wheel extrusion. With high-speed high-torque motor driving, broken objects in the crushing cavity may be fully effective crushed until they meet the specifications of the detritus. After Broken material through air maneuver sorting system, the metal and nonmetal will be left. Also the whole system is equipped with a dust removal device to minimize dust pollution generated in the production process hazards. The device has advantages of high yield, low energy consumption, high efficiency and the material is crushed uniformity. It is Low noise, no pollution, simple operation, easy maintenance in operating the machine.