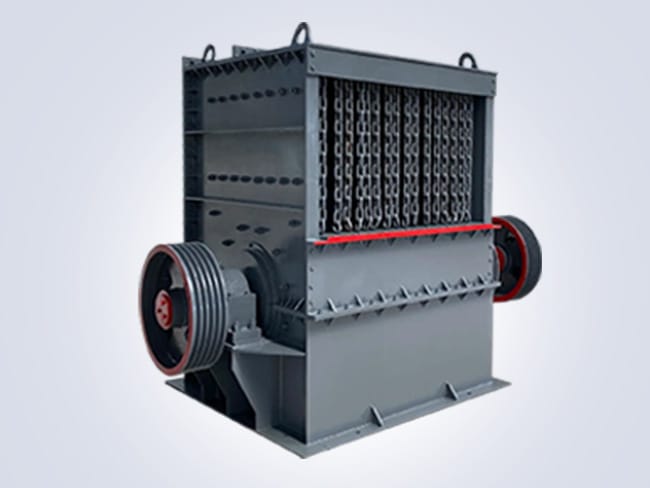

Box-Type Crusher are widely used in the mining, construction materials, and other industries. Where they operate in harsh environments and are subject to severe wear. Reducing wear is key to improving equipment lifespan and production efficiency.

How to Reduce Wear on Box-Type Crusher

Choose the Right Materials: For wear parts, selecting high wear-resistant materials is a prerequisite for reducing wear. High manganese steel, alloy steel, or composite materials are good choices.

Regular Inspection and Maintenance: Regularly inspecting the equipment and timely replacing severely worn parts play a significant role in reducing overall wear. Particularly, regular lubrication of the wear parts can effectively reduce friction and extend their lifespan.

Design the Crushing Process Reasonably: Choose the crusher model and parameters based on the characteristics of the materials and crushing requirements to avoid excessive wear due to improper selection. A reasonable feeding method and uniform feed can also effectively reduce wear.

Improve Operator Skills: The technical level of the operators directly affects the wear of the box crusher. By training, improving the operators’ familiarity with the equipment and their operating skills can effectively reduce wear caused by improper operation.

Through the above measures, wear on Box-Type Crusher can be effectively reduced, extending the equipment’s lifespan and improving production efficiency.