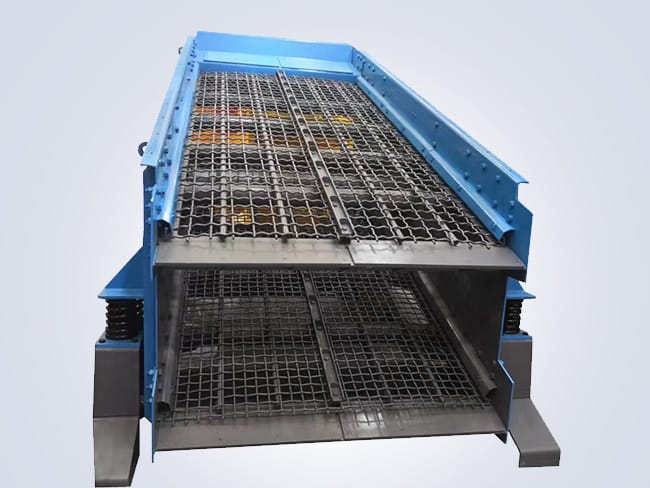

Vibrating screen play a crucial role in various industrial applications such as ore sorting, construction waste recycling, and food processing. However, the equipment may experience the phenomenon of jamming during operation, affecting its operational efficiency.

Causes of Jamming in Vibrating Screen

The jamming of the equipment is typically manifested as sudden stagnation or a noticeable slowdown in the screening process. This can be attributed to various factors, including material blockage, faults in the drive system, and failure of supporting springs. Jamming not only impacts the operational efficiency of the equipment but can also lead to equipment damage.

Analysis of Causes:

Material Blockage:

Excessive moisture or small particle size in the material can lead to blockages on the screening surface, causing the vibrating equipment to experience jamming.

Drive System Faults:

Faults in the drive system, such as motor malfunctions or slipping of the transmission belt, can result in unstable operation of the equipment.

Failure of Supporting Springs:

Damage or aging of the supporting springs in the equipment can compromise their ability to effectively dampen vibrations, leading to jamming.

Methods to Resolve Jamming in Vibrating Screen

Addressing Material Blockage:

Adjusting the material conveyance speed and screen mesh aperture can reduce the likelihood of blockages. Regularly cleaning the screen mesh ensures unobstructed operation.

Dealing with Drive System Faults:

Regularly inspecting the status of the motor and transmission belt and promptly replacing damaged components is essential. Additionally, employing a dual-drive system can enhance equipment stability and reliability.

Addressing Supporting Spring Issues:

Periodically checking the condition of the springs and promptly replacing damaged or aging springs is crucial. Increasing the support area can enhance the cushioning effect of the supporting springs.

The jamming phenomenon in vibrating screen can result from various causes. To address this issue effectively, measures should be taken based on the specific cause. Through preventive maintenance, regular inspections, and timely replacement of damaged components, occurrences of equipment jamming can be effectively minimized, thereby improving operational efficiency and equipment lifespan.