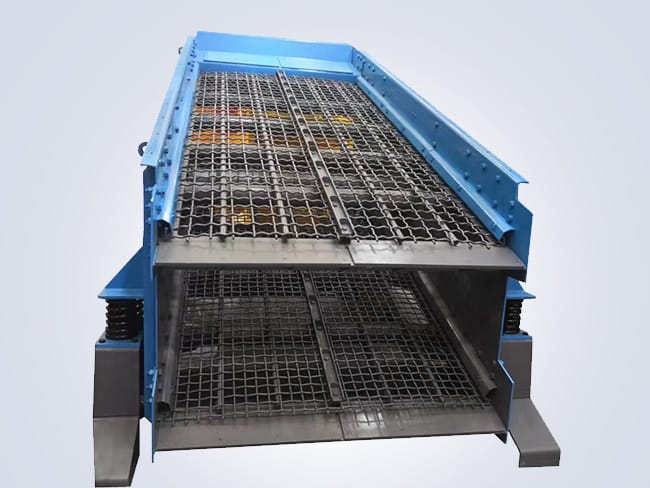

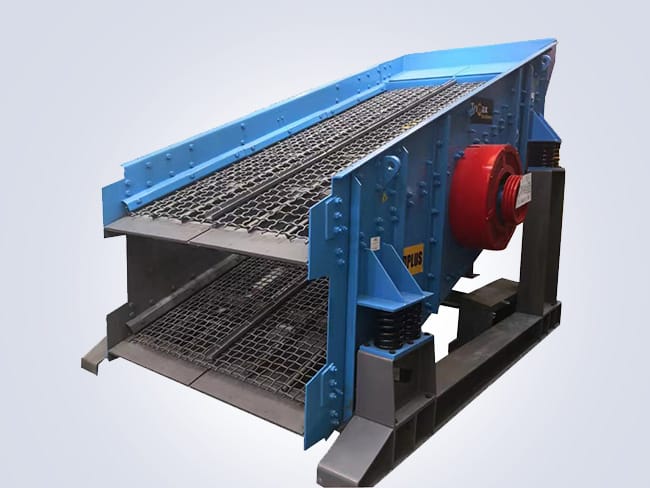

Vibrating screen, as one of the indispensable mechanical devices in modern industrial production, are of undeniable importance. They are widely used in industries such as chemical, food, pharmaceutical, metallurgy, mining, ceramics. And building materials for material grading, impurity removal, and screening. They are key equipment for improving product quality and production efficiency. Vibrating screens are critical equipment in industrial production The working principle of this equipment mainly relies on a motor driving an exciter to generate periodic vibrations. Causing the materials on the screen surface to move forward in a jumping motion. Thereby achieving the separation of materials of different particle sizes. Its design is ingenious, typically comprising a screen box, screen mesh, vibrating motor, damping springs, and other components. The material and mesh size of the screen can be customized according to different screening requirements to accommodate various material screening needs. This equipment boasts numerous advantages, such as high screening efficiency, large processing capacity, low energy consumption, low noise, and easy maintenance. It can also effectively reduce material loss, improve product purity and uniformity, and significantly enhance the economic benefits of enterprises. With the advancement of technology, this equipment is also continuously innovating and developing. For example, the introduction […]

The application prospects of the two-stage crusher are very broad, especially significant in resource regeneration and environmental protection. With the global emphasis on sustainable development, effectively utilizing and managing various types of waste has become a major challenge. This equipment performs excellently in the crushing of solid waste, such as construction debris and waste concrete. By crushing and reusing these wastes, dependency on natural resources can be reduced, environmental pollution minimized. And the development of a circular economy promoted. Two-stage crusher drive economic development In construction waste management, this equipment can crush large chunks of concrete, bricks, and other construction debris into recycled aggregates. These recycled aggregates can be used in road construction, concrete production. And other fields, saving resources and reducing the accumulation of waste, thus saving land resources. Additionally, the equipment generates less dust and noise during the crushing process, which is beneficial for environmental protection. To further enhance the performance of this equipment, researchers continuously explore new materials and technologies. For example, using new high-strength, wear-resistant alloy materials to manufacture key components of the crusher can improve its durability and crushing efficiency. At the same time, the application of intelligent control systems enables automated operation and real-time […]

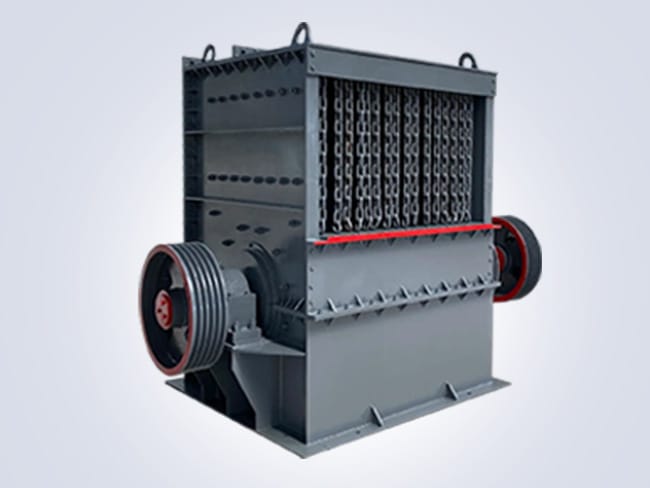

Box-type crusher is high-efficiency and energy-saving crushing equipment. Widely used in industries such as mining, building materials, highways, railways, water conservancy, and chemicals. They achieve the crushing of medium-hard materials like limestone. Coal gangue, gypsum, and bricks through the impact and shearing action between the high-speed rotating hammer and the material. Advantages of Box-Type Crusher The working principle of this equipment is to use the high-speed rotation of the hammer to violently strike the material entering the crushing chamber. The material is crushed into smaller particles under impact and extrusion. The crushed material’s discharge size is controlled by the grating bars. And materials not meeting the requirements will be crushed again until the particle size meets the standards. The impact liner inside the equipment not only enhances the crushing effect of the material. But also effectively protects the main structure of the machine. Extending its service life. Compared to traditional crushers, this equipment has several significant advantages. Firstly, it has a large crushing ratio, capable of crushing materials to the desired size in one step. Reducing the process flow of multiple crushing stages and improving production efficiency. Secondly, the equipment is simple in structure, easy to maintain, and has low maintenance […]

With the acceleration of industrialization, the amount of metal waste has been continuously increasing. Making effective handling of this waste a pressing issue. The emergence of metal crusher provides an efficient solution for recycling metal waste. The Importance of Metal Crusher Metal crusher primarily use mechanical force to break large pieces of metal waste into smaller particles. Which can then be further smelted or processed to re-enter the production cycle. Their working principles include shearing, tearing. And extrusion, enabling metal waste to be broken down to specified sizes in a short time. Thanks to advanced technology, modern metal crushers are characterized by high efficiency, low energy consumption, low noise, and low dust emissions. The application range of these devices is very broad. They can handle common metals such as steel, aluminum, and copper, as well as large waste items like old cars, household appliances, and obsolete steel structures. For the treatment of old cars, these machines can quickly crush the entire vehicle, separating steel, plastic, rubber, and other materials, thus improving the recycling rate of resources. Additionally, they can process waste generated during industrial production, such as steel rebar ends and scrap steel plates. In terms of environmental protection, the […]

The box-type crusher, widely used in various fields such as ore mining, construction material processing, metallurgy. And chemical industry. Plays a crucial role in efficiently crushing large materials into smaller pieces to meet subsequent processing or utilization needs. This equipment is highly valued in industrial production due to its robust durability, strong processing capacity, and easy maintenance. Box-Type Crusher Meets Ore Crushing Needs The working principle of this equipment primarily involves two sets of counter-rotating crushing rollers that crush the material fed into the crushing chamber through compression and shearing. These crushing rollers are typically equipped with wear-resistant materials to enhance their handling capacity for hard materials. The material, continuously compressed between the two rollers, is broken into smaller particles. With the particle size controlled by adjusting the gap between the rollers according to production requirements. A significant advantage of this equipment is its high flexibility, allowing it to accommodate various materials. Including stones, coal, ceramics, glass fragments, and other hard or medium-hard materials. Additionally, the equipment is designed with automatic detection and overload protection systems. Which automatically shut down the machine when encountering uncrushable objects. Effectively protecting the machine from damage and extending its service life. With continuous technological […]

As the industrialization process accelerates and market demand diversifies, vibrating screen. As key equipment for material classification and processing, exhibit clear trends towards high efficiency, intelligence, and environmental sustainability. Development Trends of Vibrating Screen The primary trend is the significant improvement in screening efficiency and precision. In response to the higher requirements for fine material processing in various industries. Ultrasonic technology is continuously optimized to achieve more precise screening results without sacrificing throughput. This not only promotes technological innovation in screening equipment but also drives industrial upgrading across the entire sector. Secondly, multifunctional integration has become a new highlight. Future vibrating screen will not be limited to a single screening function but will develop towards integrating multiple functions such as cleaning, drying, and measuring. This is to meet the complex needs of different application scenarios, enhancing the comprehensive utilization and economic value of the equipment. The shift towards intelligence cannot be ignored. By combining the Internet of Things (IoT), big data, and artificial intelligence technologies, these devices are gradually realizing remote monitoring, fault warning, and automatic adjustment functions. This not only significantly increases production efficiency but also reduces operating costs, aligning with the trend of smart manufacturing. Environmental protection and […]

The box-type crusher is a long-standing. And widely used primary crushing equipment that holds a significant position in industries such as mining. Building materials, metallurgy, and coal. Its design is based on the simple “compression crushing” principle. Where the relative movement of the movable jaw plate and the fixed jaw plate compresses and shears the materials fed into the crushing chamber. Achieving large block material crushing. The box-type crusher achieves crushing of various materials The core competitiveness of this equipment lies in its powerful crushing capacity and exceptional stability. With a simple and sturdy structure, it can easily handle large blocks of materials with varying hardness, such as rocks, ores. And coal, making it especially suitable for the first crushing process in mining operations. Its large opening design allows for quick and easy feeding, enhancing work efficiency. Additionally, the wear-resistant materials of the jaw plates and the optimized tooth design ensure high-efficiency and stable crushing performance over extended periods of operation. Beyond its basic crushing function, the device now incorporates multiple technological innovations to meet the evolving market demands. For instance, the hydraulic adjustment system allows operators to quickly adjust the discharge opening size. Thereby flexibly controlling the particle size […]

In today’s society, with the increasing scarcity of resources and the growing awareness of environmental protection. Metal recycling and reuse have become a crucial component of sustainable development. The metal crusher, as a key piece of equipment in this process, plays an irreplaceable role. It efficiently and environmentally crushes various scrap metal materials, laying the foundation for subsequent sorting, smelting, and re-production. Design Advantages of Metal Crusher The working principle of this equipment primarily involves using high-strength crushing components such as hammers. And blades to exert strong impact and shear force on the scrap metals fed into the machine. These scrap metals include waste steel, waste aluminum, scrapped car bodies, and obsolete household appliances. This process significantly reduces the volume of metal waste, enhancing storage and transportation convenience. It also makes it easier to separate impurities from the metal materials, thereby increasing the purity and value of the recycled metals. Modern metal crusher designs focus on combining high efficiency with low energy consumption. They incorporate advanced noise control technology and dust collection systems to minimize environmental impact. Some high-end models are also equipped with intelligent control systems, which can automatically adjust the shredding force and speed based on the characteristics […]

A box-type crusher, as a widely used device in the fields of mineral processing. Building materials production, and solid waste treatment. Primarily functions by effectively crushing large chunks of material through a combination of compression. shearing, and grinding. These machines are designed to be robust and durable, capable of handling various hard materials such as stone, coal. Concrete blocks, and metal waste. They are key equipment for enhancing material processing efficiency and reducing subsequent processing costs. Box-Type Crusher provide support for the industry The working principle of this equipment is mainly based on a closed crushing chamber. Which contains a movable jaw plate and a fixed jaw plate. When the equipment operates, the motor drives the movable jaw plate to make a reciprocating motion through the transmission system, forming intermittent closures with the fixed jaw plate, applying strong compressive force to the materials entering the crushing chamber, thereby achieving material crushing. It has a high crushing ratio and uniform discharge particle size. The discharge port size can be adjusted to control the final product size according to different needs. The advantages of this type of equipment are significant. Firstly, its simple structure and ease of maintenance reduce downtime and maintenance […]

In today’s society, with the acceleration of industrialization and the deepening of the concept of resource recycling. Metal crusher is playing an increasingly important role as core equipment in the recycling of resources. This is not only because they can efficiently process various scrap metal materials, such as scrapped cars. Discarded household appliances, and metal parts from construction waste, turning them into reusable raw materials. But also because of their significant contribution to environmental protection and the sustainable use of resources. Metal Crusher Meet Green Production Requirements The working principle of these machines is based on powerful mechanical force, using hammers, jaws. Or rollers to crush, squeeze, or shear the incoming metal waste, reducing large metal pieces to the required size. This process demands not only high efficiency. And stability from the equipment but also good adaptability to handle metals of different hardness and materials. Modern metal crushers are often equipped with advanced dust. And noise control devices to minimize environmental impact during operation, meeting green production standards. In addition to direct environmental benefits, the application of these machines greatly promotes the development of a circular economy. The metal fragments produced after shredding are easy to transport and store, and […]

The box-type crusher, as a highly efficient equipment for mining and building material processing. Is widely used in fields such as ore crushing, construction waste recycling, and cement production. Its intricate design and robust structure make it particularly suitable for coarse. And fine crushing operations of medium-hard materials, making it one of the indispensable mechanical devices in modern industrial production. The Indispensable Role of the Box-Type Crusher The core advantage of this equipment lies in its box structure design. This structure not only withstands immense impact forces, ensuring the stable operation of the machine. But also effectively reduces noise and vibration during operation, thereby improving the quality of the working environment. The machine is equipped with replaceable crushing plates and screens inside. Allowing users to flexibly adjust according to the size and hardness of the materials to be crushed. Achieving the desired crushing effect and particle size distribution. In terms of operation and maintenance, the equipment focuses on user-friendly design, employing an automated control system to simplify the operation process and improve work efficiency. Additionally, it features good accessibility for routine inspections and quick replacement of worn parts, reducing maintenance costs and downtime. Moreover, some advanced box-type crushers have incorporated […]

In today’s society, the recycling of resources has become one of the key strategies for promoting sustainable development. Metals, as indispensable materials in industrial production and daily life, are particularly important in terms of their recycling and reuse. metal crusher, serving as crucial equipment in this process, play a vital role in transforming scrap metal into reusable resources. metal crusher Reduce Dependence on Resources As the name suggests, a metal shredder is a specialized mechanical device used for crushing various large pieces of metal waste. It is widely applied in the processing of scrap steel, waste aluminum, scrapped vehicles, discarded appliances. And metal waste generated from construction demolition. Through an efficient shredding process, these originally hard-to-handle bulky metal wastes are reduced to smaller, more uniform sizes. Which not only facilitates transportation and storage but also improves the efficiency and quality of subsequent smelting processes. These devices are typically equipped with powerful shredding power systems and durable, wear-resistant shredding chambers. Capable of handling metal materials of various hardness and thicknesses, from thin aluminum cans to heavy steel. Advanced models also incorporate intelligent control technologies such as automatic feeding, overload protection. And remote monitoring functions to ensure operational safety and production efficiency. […]