As one of the core pieces of equipment in the industrial crushing field, the hammer crusher is widely used in multiple industries such as mining, building materials, chemicals. And metallurgy, thanks to its efficient and flexible characteristics. Its working principle involves impact crushing of materials through high-speed rotating hammers, making it suitable for coarse, medium. And fine crushing operations of medium- to low-hardness materials. Hammer Crusher: A Competent Equipment for Efficient Crushing Across Multiple Fields In the mining sector, hammer crushers are commonly employed for primary crushing of ores such as limestone and coal gangue. Their simple structure and ease of maintenance significantly enhance production efficiency. In the building materials industry, these crushers can break down construction waste. And concrete blocks into recycled aggregates, facilitating resource recycling. In the chemical and metallurgical industries. The equipment is used to process raw materials such as coal, coke, and salt, ensuring uniform particle size to meet subsequent process requirements. Compared to traditional crushing equipment, hammer crushers offer advantages such as a large crushing ratio, low energy consumption, and adjustable product particle size. In recent years, with technological advancements, new-generation hammer crushers have further improved their wear resistance. And processing capacity by optimizing hammer […]

In the current context where natural sand resources are increasingly depleted, the sand-making machine. With its characteristics of high efficiency and environmental friendliness, has become an indispensable core piece of equipment in the modern construction sector. As a key tool for artificial sand production, this equipment transforms raw materials such as granite, limestone. and river pebbles into manufactured sand with uniform particle size and reasonable gradation through processes including impacting, squeezing, and grinding, effectively filling the supply gap of natural sand. Sand-Making Machine: The “Sand and Gravel Revolutionary” in the Construction Field Its application scenarios span the entire infrastructure industry chain: In highway construction, manufactured sand can replace natural sand to prepare high-performance concrete. significantly enhancing pavement crack resistance; in hydropower projects, the fine aggregate produced by sand-making machines meets the stringent standards for dam cutoff walls; even in industrial sectors such as glass and ceramics, by adjusting the parameters of this equipment, customized production of silica sand raw materials with specific particle sizes can be achieved. With technological advancements, new-generation sand-making machines have undergone intelligent upgrades—equipped. With vibration sensors to monitor operational status in real-time, featuring dust removal systems that keep particulate emissions below 10mg/m³. And reducing energy consumption […]

In the crushing operations of numerous industries such as mining, building materials, and chemical engineering. The jaw crusher can be regarded as a “vanguard and powerful tool,” playing an irreplaceable and crucial role. Jaw Crusher: The “Vanguard and Powerful Tool” for Mining Crushing A jaw crusher primarily consists of components such as a frame, moving jaw, eccentric shaft, and jaw plates. Its working principle is based on the periodic swinging motion of the moving jaw. Which exerts comprehensive forces including squeezing, rubbing, and bending on the materials to achieve crushing. When the moving jaw approaches the fixed jaw, the materials are intensely squeezed and crushed between them. When the moving jaw moves away from the fixed jaw. The crushed materials are discharged from the discharge port under their own weight. It boasts numerous significant advantages. With a large crushing ratio, it can crush large pieces of material to the required particle size in one go, simplifying the crushing process. Its simple structure and robust, durable components make maintenance and inspection relatively easy, reducing usage costs. Additionally, it has a wide range of applications, effectively crushing not only hard ores and rocks but also materials of medium hardness. With the continuous […]

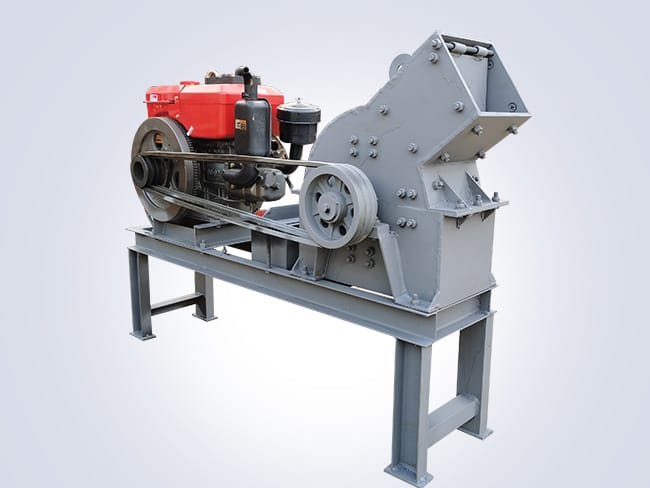

Hammer crushers are widely used crushing equipment in industries such as mining, building materials, and chemicals. Leveraging their advantages of simple structure, easy operation. And a large crushing ratio, they have become the preferred tool for crushing medium-hard and brittle materials. The core working principle involves using high-speed rotating hammers to impact, shear, and grind materials, rapidly breaking large lumps into the desired particle size. This makes them suitable for coarse, medium, and fine crushing of materials such as limestone, coal gangue, and shale. Hammer Crusher: An Efficient Industrial Crushing Tool This equipment primarily consists of a rotor, hammers, a grate bar, and a casing. The hammers are made of high-chromium alloy or manganese steel, offering both high strength and wear resistance, effectively extending their service life. The grate bar design enables precise control over the discharge particle size, ensuring uniformity of the finished product. Additionally, the hammer crusher adopts a sealed structure combined with a dust removal device, significantly reducing dust pollution and meeting environmental production requirements. With technological advancements, new-generation hammer crushers have achieved intelligent control. By adjusting the rotor speed and hammer clearance. They can flexibly adapt to different material characteristics, reducing energy consumption by over 20% […]

In the field of industrial production, the hammer crusher plays a pivotal role and serves as a capable assistant in the material crushing process. Hammer Crusher: A Powerful “Tool” for Material Crushing The hammer crusher primarily achieves material crushing by using high-speed rotating hammers to violently impact the materials. During its operation, once materials enter the crushing chamber. They are swiftly crushed by the impact of the high-speed rotating hammers. Simultaneously, the crushed materials undergo secondary collisions. And grinding with components such as impact plates and sieve bars. Further refining them until they reach the qualified particle size and are discharged through the sieve holes. It boasts numerous notable advantages. With a large crushing ratio, it can crush large lumps of material into smaller particles in one go. simplifying the crushing process and enhancing production efficiency. It has a wide range of applications, easily handling medium-hardness materials such as coal. And limestone, as well as softer materials like shale and slag. Moreover, its simple structure and ease of operation and maintenance reduce both the usage cost and maintenance difficulty of the equipment. In industries such as mining, building materials. And chemicals, hammer crushers are extensively used for primary and fine […]

As a core piece of equipment in the field of mining machinery, the sand making machine has become a crucial link in the production of sand and gravel aggregates due to its efficient and intelligent characteristics. Its core advantages are manifested in the following three aspects: Sand Making Machine: A Modern Tool for Efficient Sand Production I. High Efficiency and Energy Saving, with Outstanding Production Capacity This equipment adopts a deep-cavity rotor design, increasing material throughput by over 30%. Paired with high-strength, wear-resistant hammers, it can achieve a production capacity output ranging from 50 to 800 tons per hour. Meanwhile, the optimized power system reduces energy consumption by 20%. Combined with a hydraulic opening and closing device, maintenance and inspections are more convenient, leading to a significant decrease in overall operating costs. II. Excellent Grain Shape of Finished Products and Reasonable Gradation Through the combined crushing principles of “stone-on-stone” and “stone-on-iron,” the sand making machine can precisely control the discharge particle size. The finished sand particles exhibit a cubic shape, with a flakiness content below 5%. The fineness modulus can be adjusted within a range of 2.3-3.5. Coupled with an internal airflow self-circulation design in the vortex chamber, dust emission […]

In fields such as sand and gravel aggregate production, mining operations, and construction waste recycling. The jaw crusher has become an indispensable core piece of equipment due to its powerful crushing capabilities. As one of the earliest crushing machines to emerge, its working principle mimics the chewing motion of animals—by the periodic opening. And closing of the moving jaw plate and the fixed jaw plate, it exerts pressure, splitting, and bending forces on materials, breaking large rocks or ores into crushed stones that meet size requirements. Jaw Crusher: The “Steel Giant Jaw” of Mining Machinery The structure of a jaw crusher appears simple yet is ingeniously designed: the jaw plates, cast from high-manganese steel, offer exceptional wear resistance and can withstand hundreds of violent impacts per minute; the heavy-duty flywheel design balances power fluctuations through inertial energy storage, ensuring stable equipment operation. And the adjustable discharge port allows precise control over finished product size to meet diverse process requirements. Its advantages lie not only in its processing capacity—with models covering a full range of scenarios from several tons per hour to over a thousand tons—but also in its high adaptability to materials, efficiently crushing everything from hard granite to brittle […]

In numerous industrial fields such as mining, building materials, and chemical engineering. The hammer crusher plays a crucial role and serves as the core equipment in the material crushing process. Hammer Crusher: A Competent Assistant for Material Crushing The hammer crusher primarily achieves material crushing by using high-speed rotating hammers to violently strike the materials. Its powerful crushing capability enables it to handle materials of varying hardness, ranging from relatively soft coal. And limestone to harder materials such as iron ore and granite, all with ease. In mining operations, large chunks of ore, after undergoing preliminary crushing by this equipment, can be reduced in volume, facilitating subsequent transportation and further processing, thereby enhancing the efficiency of the entire production process. In the building materials industry, it can crush stones into aggregates of appropriate particle sizes, providing high-quality raw materials for concrete production. Moreover, the equipment has a relatively simple structure, making it easy to operate and maintain, which reduces both the usage cost and maintenance difficulty of the equipment. Additionally, with continuous technological advancements. The hammer crusher has also made significant improvements in terms of energy conservation and environmental protection. Reducing energy consumption and dust emissions during operation. It can […]

The sand-making machine is a pivotal piece of equipment in the production of sand and gravel aggregates. With its performance directly influencing the quality of the finished sand and production efficiency. Currently, mainstream sand-making machines are designed with efficiency, intelligence, and environmental protection as their core principles, boasting the following notable features: Feature Analysis of the Sand-Making Machine: The Core Equipment for Efficient Sand Production Efficient Crushing, Excellent Particle Shape Utilizing the principles of “stone-on-stone” or “stone-on-iron,” the machine achieves high-intensity impact crushing by propelling materials into. The crushing chamber via a high-speed rotating impeller. The finished sand features rounded particles, a well-graded composition, and a low flakiness content, meeting construction sand standards and being particularly suitable for high-rise buildings, bridges, and other engineering projects. Wear-Resistant and Durable, with Low Maintenance Costs Key components such as the impeller and vortex chamber are crafted from high-chromium alloys or composite wear-resistant materials, enhancing their impact resistance and wear resistance by over 50% and extending the equipment’s service life. The modular design facilitates quick replacement of wear parts, minimizing downtime and reducing long-term operational costs. Intelligent Control, High Adaptability Equipped with a variable frequency control system, the machine can adjust parameters such as […]

As the core equipment for primary crushing in industries such as mining, building materials, and metallurgy, the jaw crusher has become a “vanguard tool” for material crushing. Thanks to its unique design and reliable performance. Its key characteristics can be summarized in the following three aspects: Jaw Crusher: The “Tough Performer” in the Mining Crushing Field I. Simple Structure and High Durability The jaw crusher adopts a crushing chamber design composed of a “moving jaw + fixed jaw”. It drives the moving jaw plate to move back and forth through a crank-link mechanism. Achieving the extrusion and crushing of materials. This mechanical structure has undergone a century of optimization. Featuring a small number of standardized components and a low failure rate. Key parts such as the jaw plates and side liners are made of high-manganese steel or alloy composite materials, offering excellent impact resistance and wear resistance. Even when crushing hard materials like granite and iron ore, it can maintain long-term stable operation. II. Strong Adaptability and Wide Application It can handle various materials with a particle size of no more than 1500 mm, ranging from limestone to basalt and from wet to dry materials. Its unique deep-chamber crushing design […]

As a classic piece of equipment in mining machinery, the jaw crusher has become the “mainstay” in crushing operations thanks to its outstanding performance. Its core advantages are manifested in three major aspects: Jaw Crusher: The “Tough Performer” in the Field of Mine Crushing I. Optimized Structure for High Efficiency and Durability Featuring a deep-cavity crushing design. The material throughput is increased by 30%. When combined with the optimized motion trajectory of the moving jaw. It achieves a composite crushing action of “squeezing-splitting-bending”, enhancing the crushing efficiency by 25% compared to traditional models. The high-manganese steel jaw plates, subjected to special heat treatment, exhibit twice the wear resistance. When crushing high-hardness materials such as granite. The lifespan of key components is extended to over 18 months. II. Strong Adaptability and Wide Range of Applications It can handle large pieces of material ranging from 500 to 1500 mm, with an adjustable discharge size from 8 to 300 mm, perfectly meeting the needs of all scenarios in mining, building materials, metallurgy, and other industries. The unique wedge-block discharge port adjustment system allows for rapid particle size adjustment without stopping the machine, enabling “multi-purpose use with one machine” in sand and gravel aggregate […]

Leveraging its unique design and outstanding performance, the hammer crusher has become the preferred equipment for material crushing in industries such as mining, building materials, and chemicals. Its core advantages are manifested in the following three aspects: Hammer Crusher: An Industrial Powerhouse for Efficient Crushing I. High Efficiency and Energy Conservation with Prominent Production Capacity The hammer crusher employs a crushing method where high-speed rotating hammers impact materials, enabling “one-step forming” and reducing intermediate steps. A single unit can process thousands of tons of materials per day. With optimized rotor kinetic energy design and a scientific air pressure system, its energy consumption is reduced by over 20% compared to traditional equipment, significantly lowering operational costs. II. Strong Adaptability and Convenient Maintenance This equipment can handle a variety of materials with a hardness of ≤150MPa, such as limestone, coal gangue, and shale, and excels particularly in crushing materials of medium hardness and below. Its modular structural design allows for the replacement of wear parts like hammers and liners in just half an hour. Moreover, the hammers, crafted from high-manganese steel composite material, have a lifespan extended by three times, reducing downtime for maintenance by 60%. III. Excellent Particle Shape of Finished […]