A jaw crusher is a primary crushing equipment widely used in industries such as mining, construction, and chemicals. Its working principle mainly involves the use of two jaw plates—a fixed jaw plate. And a movable swing jaw plate—that crush materials through compression between them. Due to its simple structure, easy operation, convenient maintenance. And high crushing ratio, the jaw crusher holds an important position in mineral processing. How a Jaw Crusher Crushes Materials The core components of a jaw crusher are the two jaw plates, with one fixed to the crusher’s frame. Known as the fixed jaw plate, and the other connected to an eccentric shaft via a connecting rod. Known as the swing jaw plate. When the eccentric shaft rotates, the swing jaw plate moves back and forth. Thus achieving the compression and crushing of materials. Materials enter the crushing chamber from the feed inlet at the top. And are gradually crushed under the action of the swing jaw plate, eventually being discharged from the outlet at the bottom. The structure of a jaw crusher is relatively simple, consisting mainly of the frame, movable jaw, fixed jaw, eccentric shaft, connecting rod mechanism, spring device, and driving device. The movable […]

The core of a sand making machine lies in utilizing the high-speed rotating rotor. And impact plates to crush the raw material through impact and collision. Taking the vertical shaft impact (VSI) crusher as an example. It uses the impact force between the high-speed rotating rotor and the feed material to crush the material. And achieves shaping through the friction and wear between the materials. After the material is fed into the equipment, it is divided into two parts by the distributor. One part directly falls into the high-speed rotating impeller, where it is rapidly accelerated and then strikes the surrounding impact liner at an extremely high speed to complete the first crushing; the other part collides with the accelerated material, completing the second crushing. After multiple rounds of crushing and shaping, the material finally forms artificial sand that meets the standards. Usage Method of the Sand Making Machine To ensure the safe and efficient operation of this equipment, correct usage is crucial. Before starting the sand making machine, a comprehensive inspection is required. Including checking whether the lubrication oil pipes are securely connected and whether there are any foreign objects in the impeller. After starting, it should run idle […]

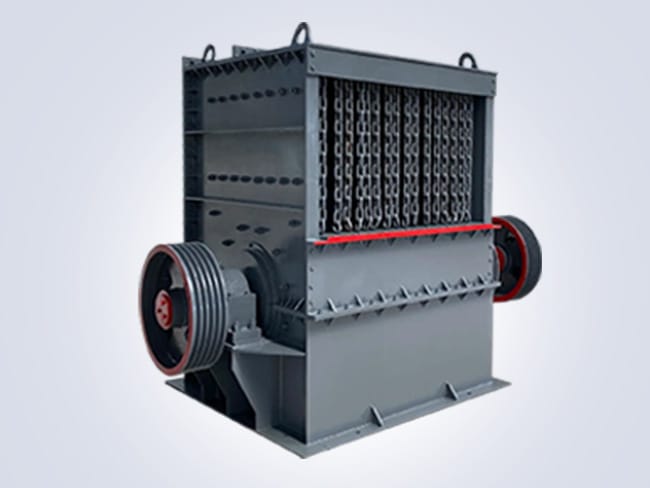

The hammer crusher is a common crushing equipment widely used in cement, chemical, electric power. Metallurgical industries for medium and fine crushing of materials with medium hardness. It occupies a significant position among many crushers due to its high crushing efficiency and relatively simple structure. Development and Improvement of Hammer Crusher The working principle of the hammer crusher mainly utilizes the high-speed rotating hammerhead to impact and crush the materials. After entering the crushing chamber, the materials are crushed by the striking of the high-speed rotating hammerhead, the counterattack of the impact plate, and the mutual collision between materials. According to the number of rotors, the equipment can be divided into single rotor and double rotor types. The single rotor can further be classified into reversible and non-reversible types. In recent years, with the progress of industrial technology and changes in market demand, this equipment has been continuously developed and improved. For example, Wei Zonghui proposed an improved design for the traditional hammer crusher to address existing issues. The improved crusher has shown longer service life and higher efficiency in practical applications. Although the hammer crusher has high crushing efficiency and a wide range of applications, it also has some […]

The jaw crusher, as a common piece of mining machinery, plays a crucial role in mining. Construction material production, highway construction, and railway engineering. This crusher is often referred to as the “tiger mouth” because its working principle is similar to the motion of an animal’s jaws to complete material crushing. Jaw Crusher Enhances Production Efficiency The equipment mainly consists of a frame, an eccentric shaft, a large belt pulley, a flywheel. Side guards, toggle plates, a back seat, an adjustment screw, a reset spring, a fixed jaw plate. And a movable jaw plate. During operation, the motor drives the eccentric shaft to rotate through a transmission device. Causing the movable jaw plate to perform periodic reciprocating movements, forming a crushing cavity with the fixed jaw plate. When the movable jaw plate approaches the fixed jaw plate, the material is crushed by compression, friction, and splitting. When the movable jaw plate moves away from the fixed jaw plate. The crushed material is discharged through the bottom discharge port of the crushing cavity by gravity. In recent years, with technological advancements and changes in social demand, the equipment has been continually improved and developed. Modern jaw crushers not only increase production […]

The “sand making machine” is a key piece of equipment in the sand and gravel industry. And its importance is self-evident. Through precise technology and powerful energy, it transforms various rocks, ores, and recycled construction waste into high-quality artificial sand. Meeting the demand for sand and gravel materials in construction, roads, bridges, and other infrastructure projects. This equipment not only enhances resource utilization but also promotes the practice of environmental protection concepts in the industrial field. Working Principle and Types of Sand Making Machine The working principle of this equipment is based on the intense impact between the high-speed rotating rotor and the material, combined with grading and plastic forming processes, to produce standard-compliant artificial sand. Common types of sand making machines include impact crushers and vertical shaft impact crushers. The former uses plate hammers for multi-stage crushing within the crushing chamber, while the latter relies on the intense impact force between the high-speed rotating rotor and the material, as well as the friction and wear between materials, to achieve fine processing of sand and gravel. Correct installation and use are crucial for the performance of sand making machines. The equipment must be securely installed on a concrete foundation, ensuring […]

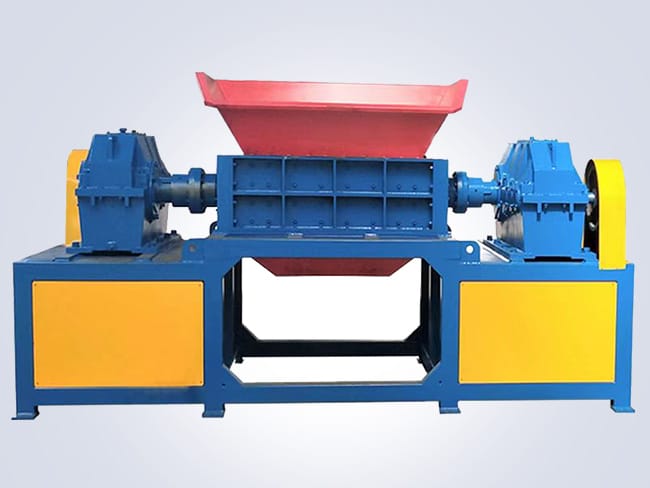

A wood shredder is a mechanical device specifically designed to process waste wood, branches, sawdust, and other biomass materials. It uses powerful mechanical forces to crush these raw materials into smaller particles or fibrous substances. This process not only effectively reduces the volume of waste. Making it easier to transport and store, but also transforms materials that might otherwise be considered garbage into valuable resources. These resources can include biomass fuel, raw materials for wood fiberboard, garden mulch. And more, achieving the recycling of waste in line with modern environmental concepts. Wood shredder Enable Waste Reutilization The working principle of a wood shredder mainly relies on the high-speed rotation of blades or hammers to cut and impact the wood entering the crushing chamber until it reaches the desired size. Some advanced models are equipped with screens. And air selection systems to ensure the consistency of the final product’s quality and specifications. Additionally, these machines are usually designed with sturdy housings and wear-resistant components to handle high-intensity operations. They are also easy to maintain and clean, ensuring long-term stable performance. In forestry, agriculture, landscaping, and the biomass energy industry, the application of this equipment is becoming increasingly widespread. It not only […]

The core advantages of a metal crusher lie in its efficient crushing capability and precise sorting technology. When waste metal enters the crusher, powerful mechanical force quickly tears it into small pieces. This process not only removes coatings, paint. And other impurities from the metal surface but also preliminarily separates different types of metals, facilitating subsequent refining and recycling. The crushed metal fragments have higher density and uniformity, making them easier to store and transport. Additionally, they are more readily accepted by smelting plants as raw materials for re-production. Metal Crusher Enhance Resource Recovery Rates Compared to traditional waste metal processing methods, this equipment significantly improves resource recovery rates, reducing energy consumption and carbon emissions. Its operating principle is based on high-speed rotating hammers or blades. Combined with a precise control system, enabling the completion of large-volume crushing tasks in a short time. To ensure a safe working environment and reduce noise pollution. Modern metal crushers are also equipped with advanced noise reduction technology and safety protection devices. This equipment has a wide range of applications, covering automobile dismantling, appliance recycling, and construction waste treatment, among other fields. As global emphasis on sustainable development and the green economy continues to […]

In the crushing industry, the box-type crusher, as an emerging crushing equipment. Is gaining prominence in various fields such as ore mining, construction material production. And waste recycling due to its unique advantages. This equipment combines modern industrial design with efficient crushing technology, providing a new solution for material handling. Significant Performance Advantages of the Box-Type Crusher The core design concept of the box-type crusher is to enclose the crushing chamber within a sturdy box. Which not only ensures the safety of the crushing process but also enhances the durability and stability of the equipment. The crushing chamber is equipped with multiple rows of hammers or blades. When materials enter, they are subjected to the impact, shearing, and grinding actions of the high-speed rotating components, thus being quickly crushed to the desired size. Compared to traditional crushing equipment, this device has significant performance advantages. Firstly, it has a high crushing efficiency and can handle materials of various hardness, including both hard and soft rocks. Secondly, its compact structure takes up a small footprint, making it suitable for operations in limited spaces. Furthermore, its sealed design effectively reduces noise and dust pollution, meeting modern industrial environmental protection requirements. The operation and […]

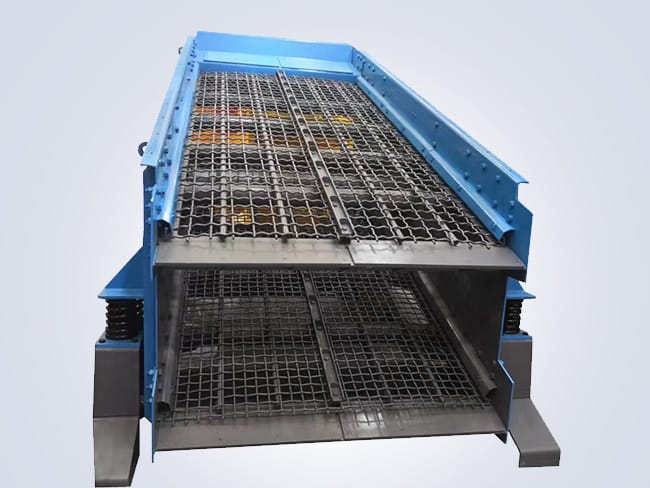

Vibrating screen, as one of the indispensable mechanical devices in modern industrial production, are of undeniable importance. They are widely used in industries such as chemical, food, pharmaceutical, metallurgy, mining, ceramics. And building materials for material grading, impurity removal, and screening. They are key equipment for improving product quality and production efficiency. Vibrating screens are critical equipment in industrial production The working principle of this equipment mainly relies on a motor driving an exciter to generate periodic vibrations. Causing the materials on the screen surface to move forward in a jumping motion. Thereby achieving the separation of materials of different particle sizes. Its design is ingenious, typically comprising a screen box, screen mesh, vibrating motor, damping springs, and other components. The material and mesh size of the screen can be customized according to different screening requirements to accommodate various material screening needs. This equipment boasts numerous advantages, such as high screening efficiency, large processing capacity, low energy consumption, low noise, and easy maintenance. It can also effectively reduce material loss, improve product purity and uniformity, and significantly enhance the economic benefits of enterprises. With the advancement of technology, this equipment is also continuously innovating and developing. For example, the introduction […]

The application prospects of the two-stage crusher are very broad, especially significant in resource regeneration and environmental protection. With the global emphasis on sustainable development, effectively utilizing and managing various types of waste has become a major challenge. This equipment performs excellently in the crushing of solid waste, such as construction debris and waste concrete. By crushing and reusing these wastes, dependency on natural resources can be reduced, environmental pollution minimized. And the development of a circular economy promoted. Two-stage crusher drive economic development In construction waste management, this equipment can crush large chunks of concrete, bricks, and other construction debris into recycled aggregates. These recycled aggregates can be used in road construction, concrete production. And other fields, saving resources and reducing the accumulation of waste, thus saving land resources. Additionally, the equipment generates less dust and noise during the crushing process, which is beneficial for environmental protection. To further enhance the performance of this equipment, researchers continuously explore new materials and technologies. For example, using new high-strength, wear-resistant alloy materials to manufacture key components of the crusher can improve its durability and crushing efficiency. At the same time, the application of intelligent control systems enables automated operation and real-time […]

Box-type crusher is high-efficiency and energy-saving crushing equipment. Widely used in industries such as mining, building materials, highways, railways, water conservancy, and chemicals. They achieve the crushing of medium-hard materials like limestone. Coal gangue, gypsum, and bricks through the impact and shearing action between the high-speed rotating hammer and the material. Advantages of Box-Type Crusher The working principle of this equipment is to use the high-speed rotation of the hammer to violently strike the material entering the crushing chamber. The material is crushed into smaller particles under impact and extrusion. The crushed material’s discharge size is controlled by the grating bars. And materials not meeting the requirements will be crushed again until the particle size meets the standards. The impact liner inside the equipment not only enhances the crushing effect of the material. But also effectively protects the main structure of the machine. Extending its service life. Compared to traditional crushers, this equipment has several significant advantages. Firstly, it has a large crushing ratio, capable of crushing materials to the desired size in one step. Reducing the process flow of multiple crushing stages and improving production efficiency. Secondly, the equipment is simple in structure, easy to maintain, and has low maintenance […]

With the acceleration of industrialization, the amount of metal waste has been continuously increasing. Making effective handling of this waste a pressing issue. The emergence of metal crusher provides an efficient solution for recycling metal waste. The Importance of Metal Crusher Metal crusher primarily use mechanical force to break large pieces of metal waste into smaller particles. Which can then be further smelted or processed to re-enter the production cycle. Their working principles include shearing, tearing. And extrusion, enabling metal waste to be broken down to specified sizes in a short time. Thanks to advanced technology, modern metal crushers are characterized by high efficiency, low energy consumption, low noise, and low dust emissions. The application range of these devices is very broad. They can handle common metals such as steel, aluminum, and copper, as well as large waste items like old cars, household appliances, and obsolete steel structures. For the treatment of old cars, these machines can quickly crush the entire vehicle, separating steel, plastic, rubber, and other materials, thus improving the recycling rate of resources. Additionally, they can process waste generated during industrial production, such as steel rebar ends and scrap steel plates. In terms of environmental protection, the […]