Metal Crusher, as crucial equipment for processing scrap metal materials, will inevitably follow the pace of technological progress. And sustainable development, exhibiting characteristics of intelligence, environmental friendliness, high efficiency, and multifunctionality in their future development. The Future Development of Metal Crusher First and foremost, intelligence is a key trend in the development of this equipment. With the deep application of artificial intelligence and machine learning technologies. Future devices will be equipped with more advanced sensors and control systems, achieving automated feeding. Intelligent adjustment of crushing force and speed, as well as automatic fault detection and alarm functions. This will enhance operational efficiency and equipment stability. Secondly, environmental friendliness will become an inevitable choice for the development of this equipment. In the context of a growing global environmental awareness, reducing energy consumption and pollution emissions become important considerations in design. Future devices will adopt more energy-efficient driving technologies and effective dust suppression and noise reduction measures to achieve a more environmentally friendly production process. Thirdly, high efficiency is a goal to pursue. Through the advancement of material science and the optimization of crushing processes, future equipment will have higher crushing efficiency and processing capacity while reducing energy consumption, thus increasing the […]

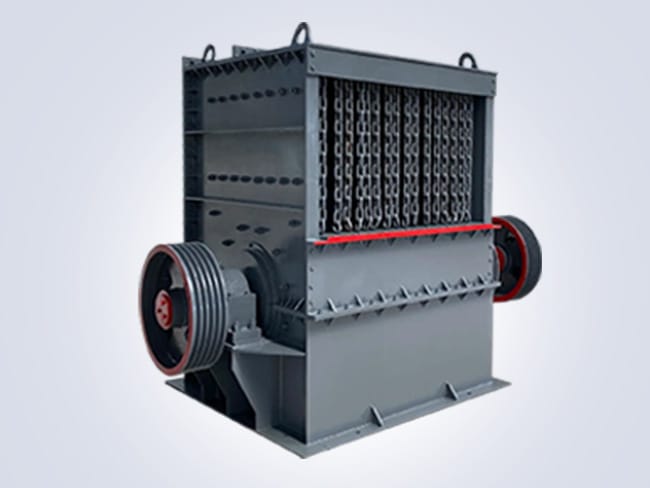

The box-type crusher, as a new type of high-efficiency crushing equipment, plays an important role in modern industrial production. It is mainly used for the coarse, medium, and fine crushing of materials and is widely applied in industries such as cement, chemical, power, and mining. Several Advantages of the Box-Type Crusher Wide Range of Applications: The box crusher can adapt to a variety of materials. Whether it’s materials with higher hardness or those with higher moisture content, it can effectively crush them, demonstrating strong adaptability. Compact Structure, Small Footprint: This crusher is designed to be compact, taking up a small footprint, which makes it easy to install and maintain. Additionally, its lightweight design makes it easy to transport and move, suitable for various complex and narrow working environments. High Crushing Efficiency: The box crusher employs advanced crushing technology, offering a large crushing ratio and high efficiency. This means it can process more materials in a shorter amount of time, increasing production efficiency. Energy-Saving and Environmental Protection: Compared to traditional crushers, the box-type crusher has lower energy consumption during operation and less environmental impact. This crusher uses a closed crushing method, effectively reducing dust and noise pollution, and meets current environmental […]

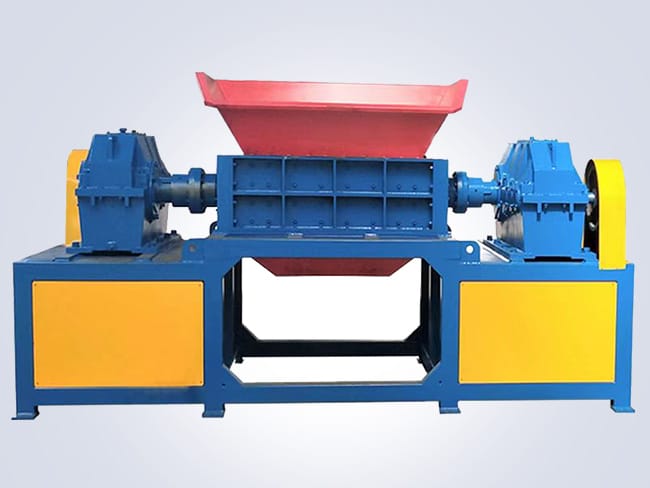

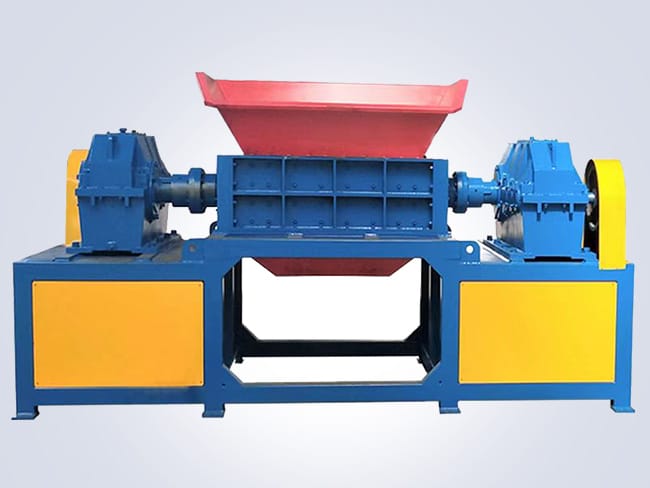

Wood shredder, as a specialized type of machinery used for processing wood into sawdust or wood powder. Play an important role in the modern wood processing industry. They are widely used in wood recycling, the preparation of biomass energy. And the handling of wood processing residues, among other fields. Advantages of Wood Shredder The main working principle of a shredder is to use rotating blades to shear, tear, and compress the wood, thereby crushing materials like wood blocks and branches into small particles of sawdust or wood powder. These blades are typically mounted on a high-speed rotating shaft, driven by a power device. The high-speed rotation of the blades, in conjunction with fixed knives, efficiently crushes the wood. These machines usually feature a compact structure, simple operation, high efficiency, and low energy consumption. Depending on different needs, shredders can be categorized into various types, such as drum-type wood shredders, disc-type wood shredders, and hammer-type shredders. Each type of machine has its own design and working principle, suitable for different scales and requirements of wood processing. Although the use of shredders brings many conveniences, there are also some issues to be aware of during their operation. For example, it’s important to […]

The box-type crusher, as a new type of crushing equipment, has been widely applied and developed in recent years. Its main characteristics include a compact structure, high efficiency. And simple operation, making it especially suitable for the crushing of large materials. This model is extensively used in mining, construction, cement, chemical, and other industries, playing a significant role in improving production efficiency and saving costs. Characteristics of the Box-Type Crusher Structurally, the box crusher mainly consists of a casing, rotor, hammerhead, and impact plate. Its unique box-type structure makes the equipment overall more robust, able to withstand greater impact forces. The rotor is a key part of the crusher, with hammerheads mounted on the high-speed rotating rotor. Rapidly crushing the materials under the high-speed impact of the hammerheads. Additionally, the impact plates inside the equipment also perform a secondary crushing role. Ensuring uniformity and fineness in the material crushing. In terms of operation, the box-type crusher is easy to maintain, and its wearing parts are convenient and quick to replace. Its efficient crushing ability not only reduces energy consumption but also improves production efficiency. Moreover, this model also has good sealing performance, reducing dust emissions, contributing to an improved […]

The two-stage Crusher is an efficient and energy-saving crushing equipment. Which is widely used in mining, construction, chemical industry and other fields. Requirements for the use of two-stage Crusher Follow the instructions strictly: Double-stage crushing is a heavy-duty equipment, which requires operation according to the instructions. Before use, it is necessary to carefully read the instructions to understand the basic parameters, usage methods, safety precautions, etc. of the equipment. Keep the equipment clean: During the working process of the two-stage Crusher, it is necessary to keep it clean to avoid debris and foreign objects entering the crushing chamber. During the production process, the residues on the equipment surface and in the crushing chamber should be regularly cleaned. Pay attention to the feed particle size: Double-stage crushing has certain requirements for the feed particle size. Materials that are too large or too small can affect the crushing effect and production efficiency. During use, ensure that the feed particle size is within the specified range. Adjust the crushing gap: The crushing gap of the two-stage Crusher has a significant impact on the crushing effect and production efficiency. During use, the crushing gap should be adjusted according to the actual situation to achieve […]

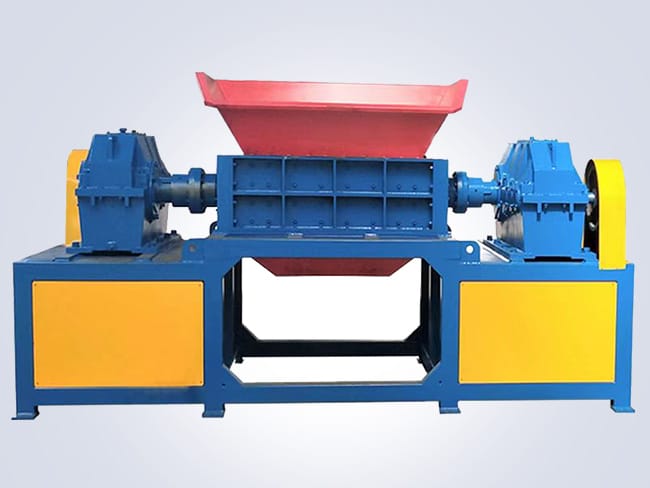

The metal crusher is a critical piece of equipment widely used in the fields of metal recycling, smelting, and waste processing. Employing advanced crushing technology. This machine efficiently crushes and separates various metal materials, providing reliable support for resource recovery and reuse. The metal crusher is capable of handling various metals Firstly, it utilizes powerful crushing force to process a variety of metal materials. Including discarded cars, obsolete appliances, metal structures, and more. Its highly adjustable crushing parameters allow it to adapt to different sizes and shapes of metal materials. Facilitating comprehensive processing of scrap metals. Secondly, the metal crusher plays a significant role in metal recycling. By crushing large pieces of metal, it effectively reduces volume, making storage, transportation, and processing more convenient. Additionally, the crushed metal fragments are easier to separate and classify, enhancing the recovery rate of scrap metals and strongly supporting the concept of resource recycling. Furthermore, it plays a crucial role in the smelting process. Pre-crushing raw materials contributes to improved smelting efficiency, reduced energy consumption, and lowered production costs. This is of great significance for the sustainable development of the metal industry. In conclusion, the metal crusher is an indispensable part of the modern […]

Box-type crusher is a commonly used crushing equipment in fields such as mining, construction. And metallurgy, playing a crucial role in material crushing and processing due to its unique structure and working principles. Key features of the box-type crusher: Firstly, the structure of the box crusher is simple yet robust. Its main components include the box body, rotor, and counterattack plate. The box body is constructed from high-quality steel. Providing high strength and wear resistance, ensuring the equipment maintains excellent stability during prolonged operation. Secondly, the box-type crusher possesses efficient crushing capabilities. When materials enter the box body, they undergo the impact and counterattack of the rapidly rotating rotor. Achieving the desired crushing effect. This efficient crushing method not only quickly reduces the particle size of the material but also adapts to materials of various hardness and humidity. Furthermore, the equipment features reliable safety protection devices. During operation, the installation of well-designed safety devices effectively prevents equipment failures caused by abnormal situations, ensuring the safety of operators and the equipment. The operation and maintenance of the box crusher are relatively straightforward, reducing operational costs. Additionally, the compact external design of the equipment requires a relatively small footprint, making it suitable […]

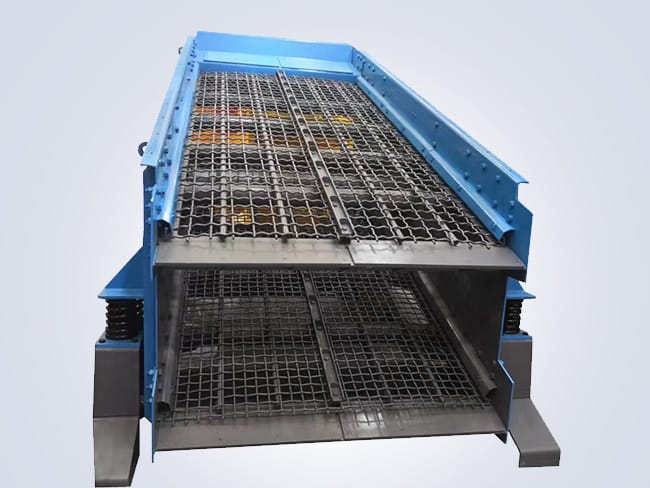

A vibrating screen is a commonly used equipment for material screening and classification, bringing numerous conveniences to the production processes across various industries. Key Advantages Brought by the Vibrating Screen Firstly, the vibrating screen possesses highly efficient screening capabilities. Through vibrational movements, it swiftly separates fine particles from larger ones in raw materials, achieving efficient material screening. This heightened efficiency not only enhances production productivity but also reduces energy consumption, making the production process more economically efficient. Secondly, the equipment boasts a wide application range. It finds utility in multiple sectors, including mining, construction materials, metallurgy, and chemical industries. Effective screening of raw materials with different particle sizes and properties makes this equipment indispensable in various industries, elevating industrial production flexibility and diversity. Moreover, the equipment’s structural design ensures stable and reliable performance. With advanced vibration technology and high-quality screen mesh materials, the equipment maintains a stable screening effect during prolonged operation, reducing the frequency of maintenance and screen mesh replacements, thus lowering operational costs. Simultaneously, the equipment is relatively straightforward to operate and maintain. Operators only need familiarity with basic operational procedures to easily grasp the equipment’s usage techniques. Maintenance is also relatively uncomplicated, significantly minimizing downtime and ensuring […]

The wood shredder is a specialized mechanical equipment designed for processing wood, primarily involving the effective crushing and processing of various types of wood. This equipment plays a crucial role in wood processing, papermaking, biomass energy, and other fields. Providing reliable technical support for the comprehensive utilization of wood resources through its efficient working mechanism. About the Operation of the Wood Shredder Firstly, the operation of the shredder begins with the input of raw materials. Various types of wood, including branches, logs, and discarded furniture, are fed into the shredder’s inlet. The machine’s interior is typically equipped with robust blades and rotating hammers, which crush the wood through high-speed rotation and impact. Secondly, the wood shredder employs a multi-level cutting and crushing technology during the crushing process. The primary crushing stage involves the cutting action of blades, reducing the wood into smaller chunks, creating conditions for subsequent processing. Subsequently, through the high-speed impact of rotating hammers, the wood enters the fine crushing stage, gradually transforming into smaller particles. During the wood shredding process, the equipment often features a sieve screen for separating particles of different sizes. This helps adjust the particle size of the final product to meet the requirements […]

The metal crusher is a specialized equipment designed for processing scrap metal. Playing a crucial role in the field of metal recycling. Through innovative crushing technology, this equipment effectively shreds various types of metal scraps into reusable particles, providing robust support for resource recycling. Crushing Process of the Metal Crusher The crushing process of the crusher begins with the introduction of scrap metal. Waste metals, such as old cars and discarded appliances, are fed into the crusher’s inlet. The interior of the equipment is typically equipped with powerful crushing blades and hammers. Which cut and impact the metal at high speeds, causing rapid deformation and fragmentation. Within the metal crusher, after the initial crushing of metal waste, it enters the fine crushing stage. At this stage, the equipment is usually equipped with fine crushing blades and sieves, further refining the metal particles to the required size. This ensures that the crushed metal particles can easily enter subsequent processing stages, such as melting or recycling. The crushing process of the metal crusher is not only efficient but also features a high level of automation and low energy consumption. Some advanced crushers are equipped with intelligent control systems, capable of automatically adjusting […]

As a common crushing equipment. The box-type crusher requires strict adherence to a series of operational precautions during use to ensure the safe operation. And efficient performance of the equipment. Operational Precautions for Box-Type Crushers: Firstly, carefully read the operation manual before using the crusher. The operation manual provides detailed information about the structure, working principles. And operating procedures of the equipment, serving as an essential reference for operators. Prior to operation, it is crucial to understand and familiarize oneself with the technical parameters and performance characteristics of the equipment, ensuring that operations are conducted in the correct sequence. Secondly, ensure that the electrical system of the crusher is in normal working condition. Before starting the equipment, check the secure connection of the electrical system, inspect for damaged cables, and verify that the electrical equipment meets safety requirements. If any abnormalities are detected, promptly perform repairs and replacements, avoiding forceful startup that may lead to irreversible damage. Additionally, operators should maintain focus while using the crusher and refrain from independently altering equipment parameters during the operation. Any changes in operations should be conducted while the equipment is in a shutdown state and carried out by trained professionals. Unauthorized parameter changes […]

As a commonly used equipment in the wood processing industry, the primary function of a wood shredder is to shred raw wood, facilitating subsequent processing and utilization. Can a Wood Shredder Effectively Shred Wet Wood? Firstly, wood shredders are typically designed with the consideration of handling wet wood. Compared to dry wood, wet wood contains higher moisture content, presenting additional challenges during the crushing process. However, many modern shredders are equipped with robust driving systems and specially designed blades. Enabling them to effectively process wood with higher humidity. Secondly, shredders usually operate on the principle of blade crushing rather than relying on high-temperature drying of wood. This makes them well-suited for handling wood with higher moisture content. Even if the wood contains a certain amount of moisture. The blade design of the shredder can efficiently cut and shred wet wood without causing excessive resistance or damage to the machine. However, it is important to note that while the equipment can handle wet wood. Excessively high humidity may still have some impact on the machine’s lifespan and performance. Therefore, when using the equipment to process wet wood. It is advisable to ensure that the wood moisture is within a reasonable range […]