In numerous industrial production processes, vibrating screen play a significant role as crucial screening and grading equipment. They efficiently and accurately separate solid materials of different particle sizes, ensuring the quality and efficiency of subsequent processing steps. Vibrating screens find wide applications in industries such as mining, chemical, food processing, pharmaceuticals, and construction materials.

The equipment mainly relies on electric motor-driven exciters to generate reciprocating or rotary vibrations. Causing the screen surface to move periodically. When materials are evenly distributed on the screen surface. This vibration causes fine particles smaller than the screen openings to pass through the mesh. While coarse particles larger than the openings remain on the screen surface, thereby achieving material classification by particle size. Depending on various application requirements, the equipment can be designed to operate in multiple motion modes, such as linear vibration, circular vibration, or rotary vibration.

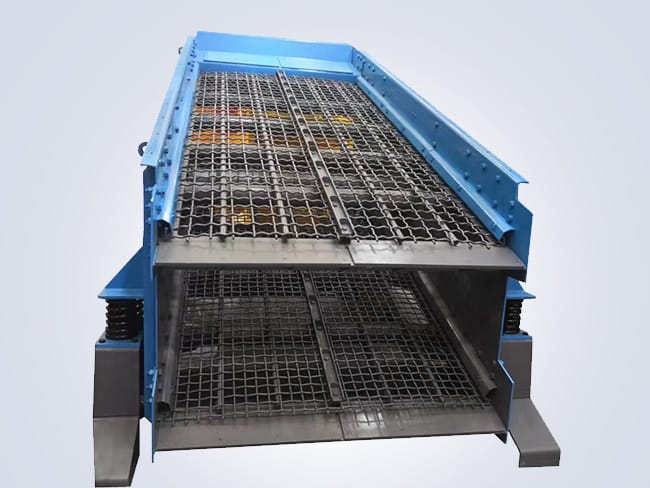

A vibrating screen typically consists of components such as the screen box, screen mesh, vibrating motor, shock absorber springs, and support devices. Among these, the screen mesh, as a core component. Directly affects the screening efficiency and accuracy based on the material and opening size selection. Modern vibrating screen designs emphasize the convenience of replacing vulnerable parts and the stability of the entire machine, utilizing high-quality wear-resistant materials to prolong service life and reduce maintenance costs.

Advantages of Vibrating Screen

1.Efficient Screening: High-frequency vibrations ensure rapid loosening and layering of materials on the screen surface, significantly improving screening efficiency and throughput.

2.Precise Grading: Multi-layer screen designs enable multiple-stage grading with a single feed, meeting precise particle size requirements across different industries.

3.Wide Applicability: Vibration parameters and screen configurations can be adjusted according to different material characteristics and screening needs, accommodating a variety of material screening operations.

4.Easy Maintenance: Reasonable structural design facilitates routine inspection and maintenance, reducing downtime and ensuring continuous operation of production lines.

In summary, vibrating screen serve as an important component in material processing workflows. Continuous improvement in their performance is crucial for enhancing production efficiency and ensuring product quality, making them essential drivers for industrial upgrading and green development.