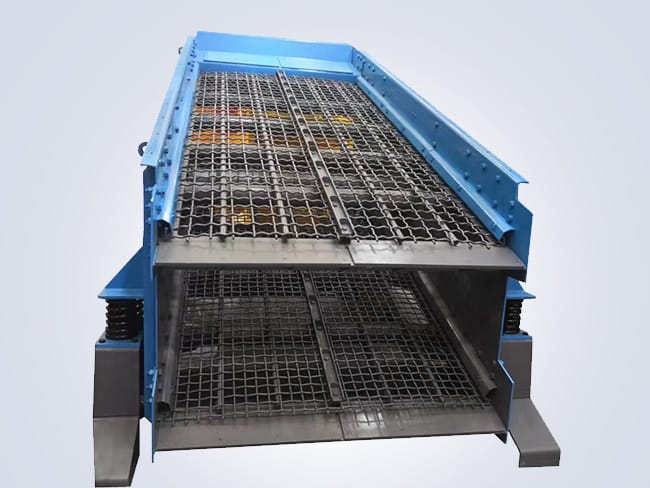

The vibrating screen is a widely used screening equipment in multiple industries such as mining, metallurgy, chemical, and building materials. Primarily for the classification, screening, and filtering of materials. It operates through a vibration motor or other forms of driving force, causing the screen surface to vibrate, making the materials attached to the screen surface jump or move forward, thus achieving the separation of particles of different sizes.

Adapting to New Requirements with Vibrating Screen

The design of vibrating screens is diverse, including circular, linear, high-frequency, and other types, to meet the needs of different materials and working conditions.

The core advantage of this equipment lies in its high screening efficiency and large processing capacity. Additionally, the vibration frequency and amplitude can be adjusted according to the characteristics of the materials and user demands. Achieving better screening results. However, regular maintenance and care are also necessary during the use of this equipment to avoid wear and tear caused by excessive vibration force, ensuring long-term stable operation.

With technological advancements, the design and performance of vibrating screens are continuously optimized. Such as the adoption of advanced vibration sources and the addition of automatic screen cleaning devices. Further improving screening efficiency and service life to meet the increasingly strict requirements of industrial and mining screening. As an indispensable piece of equipment in modern industrial production, the future development of this equipment will focus more on intelligence, efficiency. And environmental friendliness, to adapt to the new requirements of global economic development.