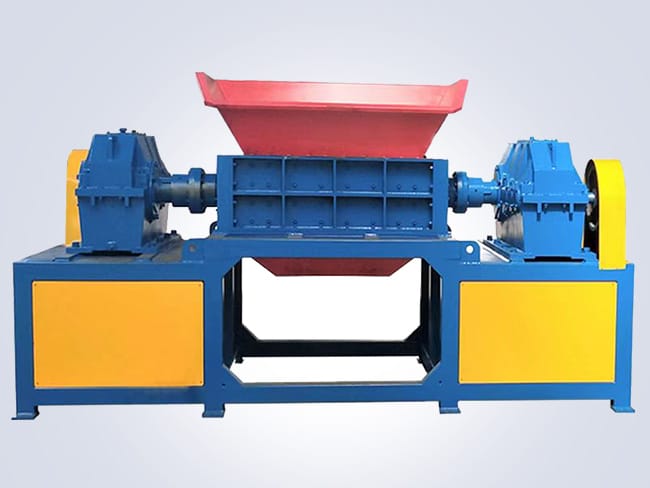

The wood shredder is a specialized mechanical equipment designed for processing wood, primarily involving the effective crushing and processing of various types of wood. This equipment plays a crucial role in wood processing, papermaking, biomass energy, and other fields. Providing reliable technical support for the comprehensive utilization of wood resources through its efficient working mechanism.

About the Operation of the Wood Shredder

Firstly, the operation of the shredder begins with the input of raw materials. Various types of wood, including branches, logs, and discarded furniture, are fed into the shredder’s inlet. The machine’s interior is typically equipped with robust blades and rotating hammers, which crush the wood through high-speed rotation and impact.

Secondly, the wood shredder employs a multi-level cutting and crushing technology during the crushing process. The primary crushing stage involves the cutting action of blades, reducing the wood into smaller chunks, creating conditions for subsequent processing. Subsequently, through the high-speed impact of rotating hammers, the wood enters the fine crushing stage, gradually transforming into smaller particles.

During the wood shredding process, the equipment often features a sieve screen for separating particles of different sizes. This helps adjust the particle size of the final product to meet the requirements of various application fields. For example, biomass pellet fuel requires a relatively uniform particle size, while the papermaking industry may require finer wood fibers.

In summary, the wood shredder, through its efficient and multi-level crushing operation, provides crucial support for the comprehensive utilization of wood resources. The application of this equipment helps reduce the waste of wood materials, improve the utilization efficiency of wood resources. And simultaneously promotes the development of biomass energy and the circular economy.