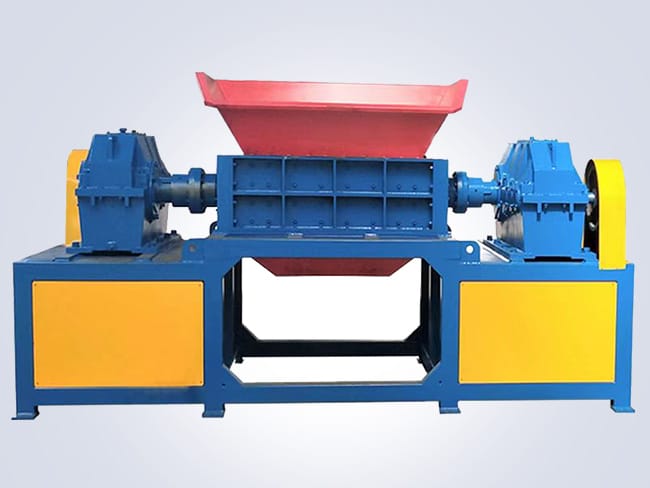

As a commonly used equipment in the wood processing industry, the primary function of a wood shredder is to shred raw wood, facilitating subsequent processing and utilization.

Can a Wood Shredder Effectively Shred Wet Wood?

Firstly, wood shredders are typically designed with the consideration of handling wet wood. Compared to dry wood, wet wood contains higher moisture content, presenting additional challenges during the crushing process. However, many modern shredders are equipped with robust driving systems and specially designed blades. Enabling them to effectively process wood with higher humidity.

Secondly, shredders usually operate on the principle of blade crushing rather than relying on high-temperature drying of wood. This makes them well-suited for handling wood with higher moisture content. Even if the wood contains a certain amount of moisture. The blade design of the shredder can efficiently cut and shred wet wood without causing excessive resistance or damage to the machine.

However, it is important to note that while the equipment can handle wet wood. Excessively high humidity may still have some impact on the machine’s lifespan and performance. Therefore, when using the equipment to process wet wood. It is advisable to ensure that the wood moisture is within a reasonable range to minimize adverse effects on the equipment.

In summary, wood shredders are generally effective in processing wet wood, but users should take appropriate preprocessing measures based on actual conditions to ensure the smooth operation and prolonged lifespan of the equipment.