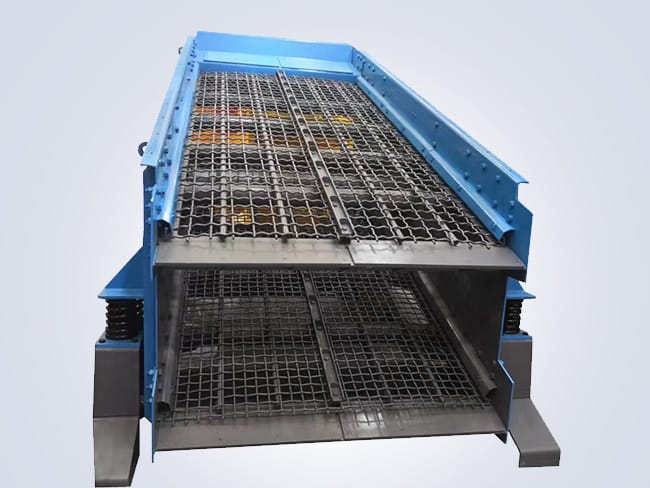

The vibrating screen, as an efficient particle screening device, finds wide applications in various industrial fields. Its unique vibrating motion makes it an ideal choice for particle separation and screening.

Firstly, the equipment utilizes vibration force to classify materials into different particle sizes. It is equipped with eccentric blocks or vibration motors inside, generating high-frequency vibrations that cause materials to jump on the screen, achieving separation. This high-frequency vibration has strong penetration, effectively screening small particles and improving production efficiency.

The vibrating screen enhances the working environment of production lines

Secondly, the vibrating screen features a multi-layer screen structure, capable of simultaneously separating multiple particle sizes. Different layers of screens can be adjusted based on particle size, meeting diverse particle size separation requirements. This multi-layer screening structure allows the vibrating screen to be widely used in various fields such as chemical, food. And pharmaceutical industries.

Additionally, the vibrating screen employs advanced materials and manufacturing processes, offering excellent properties such as wear resistance and corrosion resistance. The screen mesh is made of high-strength materials, which are not easily worn out, significantly extending its lifespan and reducing maintenance costs. Moreover, the equipment operates stably, produces low noise, and is easy to operate, greatly enhancing the working environment of production lines.

In summary, this equipment, with its efficient particle screening capabilities, multi-layer screening structure, and superior durability, becomes the preferred choice for separating various particle materials. It plays a crucial role in improving production efficiency, reducing costs, and enhancing the production environment. With the continuous progress of technology, its performance will further improve, providing stronger support for the development of various industries.