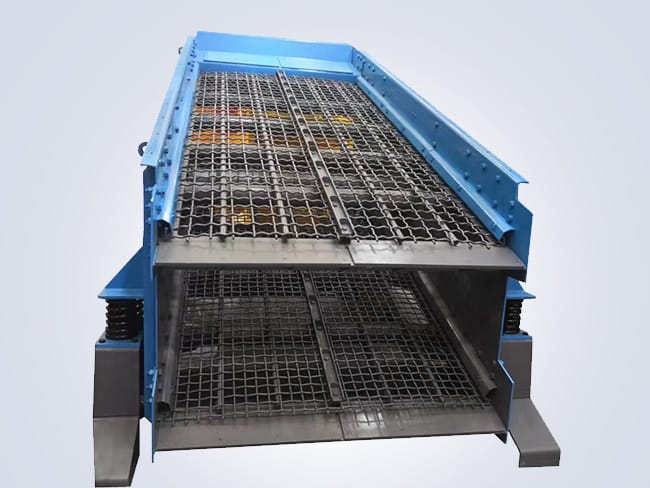

A vibrating screen is a widely used mechanical device for the screening and separation of granular materials. Its working principle involves using vibration to classify materials into different particle sizes. Vibrating screens find significant applications across various industrial sectors, including food processing, mining, metallurgy, construction, and chemical industries.

The operating principle of this equipment is straightforward yet highly efficient. It typically consists of one or more screen layers, each equipped with small holes or mesh. When the vibrating screen is activated, the vibrating force generated by an electric motor or vibrator causes materials to continuously move on the screen surface. Smaller particles pass through the screen openings and drop into containers below, while larger particles are retained on the screen layers.

Vibrating screens offer several advantages

Efficient Screening: Through continuous vibration, this equipment rapidly and efficiently separates materials, thereby improving production efficiency.

Versatility: It is suitable for a wide range of materials, including particles, powders, liquids, and more, making it widely applicable in diverse industrial fields.

Adjustability: The vibration force and amplitude of the equipment can be adjusted as needed to meet different material and screening requirements.

Automation: It can be integrated into automated production lines, facilitating continuous screening and separation processes while reducing manual intervention.

Environmentally Friendly: Vibrating screens do not require additional screening media, reducing waste and pollution.

Despite its excellent performance across various applications, some key considerations should be observed during use. Regular cleaning, maintenance, and inspection of the screen layers to assess wear and tear are essential to ensure the equipment’s smooth operation and longevity.

In summary, vibrating screens serve as efficient tools for particle screening and separation, finding widespread use in industrial production. Their simple yet reliable operating principle enables precise particle separation, offering reliable solutions for production processes across various sectors.