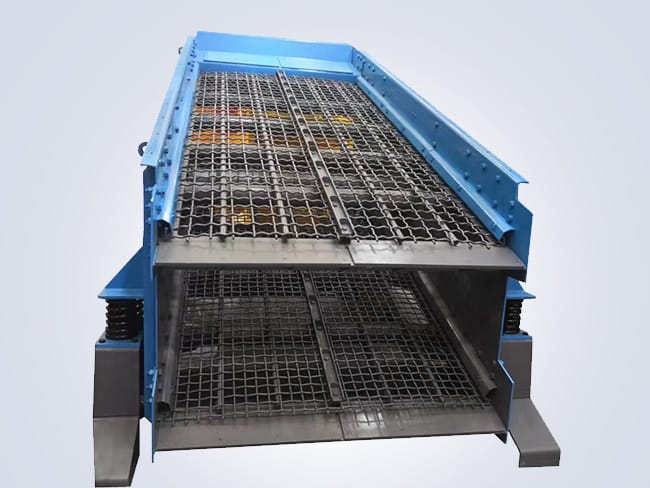

The vibrating screen is a common screening device extensively employed for particle materials’ classification, separation, and filtration. Its operational principle relies on subjecting materials to vibration forces, guiding them through sieve openings, thereby segregating particles of varying sizes to meet the diverse needs of various industrial sectors.

How to achieve particle classification by vibrating screen

This equipment generates vibration forces via a vibration motor, inducing cyclic vibrations in both horizontal and vertical directions. During this process, particle materials jump and roll on sieve openings, effectuating particle classification. By configuring different sieve openings, varying particle sizes of end products can be achieved.

This equipment finds broad applications across sectors such as mining, metallurgy, chemical engineering, and food processing. In mining, the vibrating screen segregates raw ores according to different particle sizes, yielding the desired mineral products. In food processing, it sieves raw materials, eliminating impurities to enhance product quality.

Its key advantage lies in its efficient and rapid screening capabilities. Through the action of vibration forces, particle materials swiftly pass through sieve openings, achieving efficient separation. Additionally, the vibrating screen can be adjusted based on material characteristics to attain optimal screening results.

What are the precautions for using equipment

However, during use, attention must be given to factors like material humidity and viscosity to prevent sieve blockages and equipment malfunctions. Furthermore, the operation and maintenance of the vibrating screen should adhere to relevant operational guidelines and safety requirements.

In conclusion, as a prevalent screening device, the vibrating screen realizes particle material classification and separation through vibration forces. Its broad applicability spans multiple sectors, and its rapid and efficient screening capabilities provide dependable support for material processing, fostering the progress and development of industrial production.